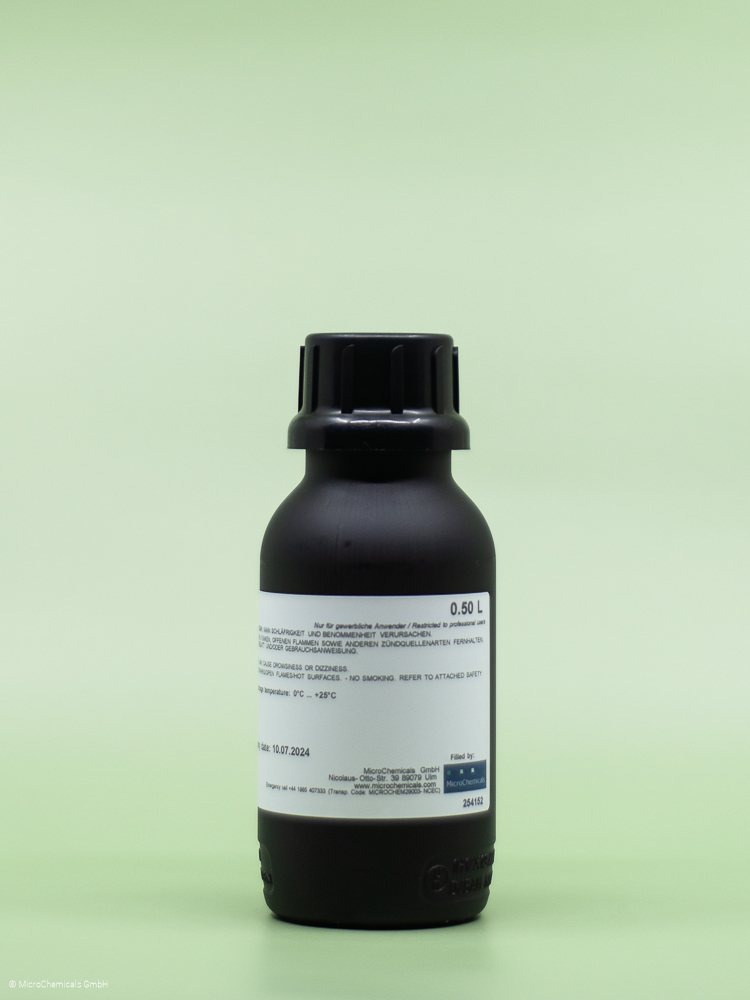

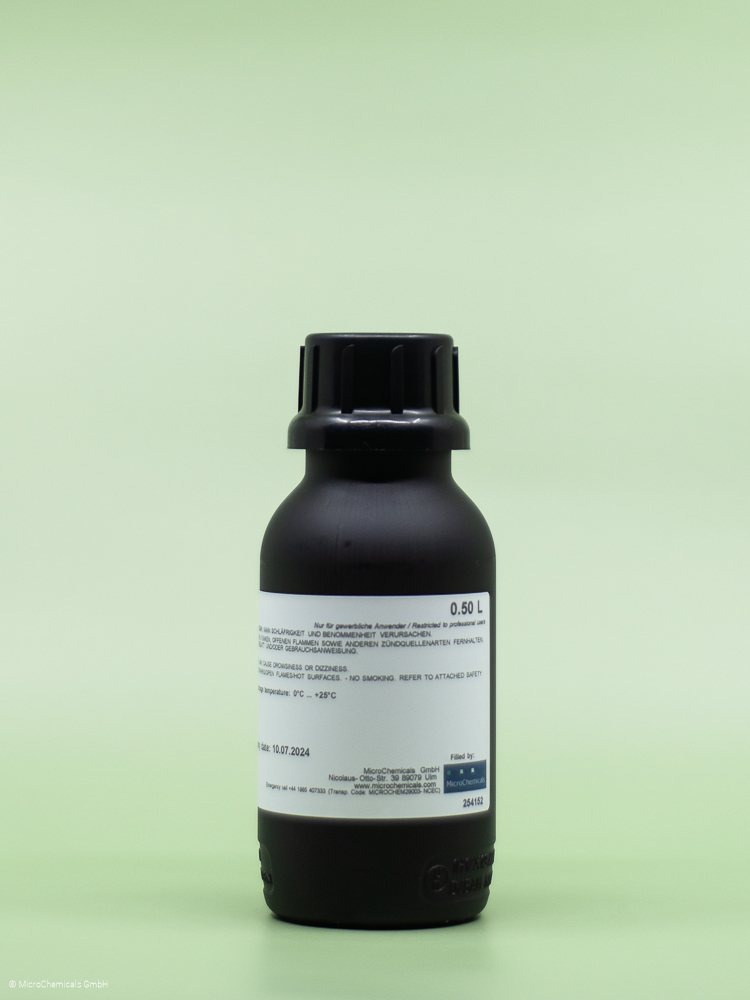

AZ NLOF 2035 Photoresist - 0.50 l

Product information "AZ NLOF 2035 Photoresist - 0.50 l"

AZ® nLOF 2035

Thick Negative Resist for Lift Off

General Information

The i-line sensitive negative resist AZ® nLOF 2035 with a resist film thickness of approx. 3 - 4 µm is a member of the AZ® nLOF 2000 series, which is primarily optimized for lift-off applications.

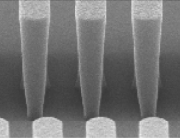

700 nm resist lines attained with the 3.5 µm thick AZ® nLOF 2035.

Product Properties

AZ® nLOF 2035 covers a resist film thickness range of - depending on the spin speed - approx. 3 - 4 µm. It is only i-line sensitive and requires a post exposure bake after exposure to complete the cross-linking induced during exposure. The developed resist structures are pronounced negative, as desired for lift-off applications, since the upper resist areas receive a higher dose during exposure and thus cross-link more strongly than the resist areas close to the substrate. Using a lower exposure dose, in conjunction with a slightly hotter post exposure bake, this undercut can be increased to a certain extent to enable even more critical lift-off applications. If thinner resist layers are desired, the AZ® nLOF 2035 can be diluted with PGMEA = AZ® EBR Solvent or the AZ® nLOF 2020 can be used. For thicker layers, the AZ® nLOF 2070 (> 5 µm) is recommended; both differ from the AZ® nLOF 2035 only in the solvent content.

Developers

TMAH-based developers such as the ready-to-use AZ® 326 MIF (immersion development), AZ® 726 MIF (puddle development) or AZ® 2026 MIF (which uses an additive to promote residue-free development, especially with cross-linking resists) are recommended for developing the AZ® nLOF 2035. KOH- or NaOH-based developers such as the AZ® 400K or AZ® 351B are generally not suitable for the AZ® nLOF 2035. If TMAH-based developers cannot be used, an attempt with a KOH-based developer in higher concentration than usual can be considered.

Removers

If the resist structures have not been thermally cross-linked too much, for example through metallization, stripping or lift-off with organic solvents (acetone rinsed with isopropanol or DMSO) can be successful. For more strongly cross-linked resist structures, high-performance strippers such as the NMP-free TechniStrip NI555 or AZ® 920 Remover are recommended, or in the case of alkaline-sensitive substrate materials (such as aluminum), the TechniStrip MLO 07.

Thinning/ Edge Bead Removal

If the resist is to be diluted for spin coating, PGMEA = AZ® EBR Solvent is an option. PGMEA is the solvent for AZ® nLOF 2035 anyway and is also recommended for edge wall removal if necessary.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® nLOF2035 Photoresist english

Safety Data Sheet AZ® nLOF2035 Photoresist german

TDS:

Technical Data Sheet AZ® nLOF2000 Series english

Information AZ® nLOF2000 Series english

Information AZ® nLOF2000 Series german

Application Notes:

Further Information about Photoresist Processing

Related products

Developer

Remover