BOROSILICATE GLASS WAFERS

Borosilicate glass and normal glass in comparison

Composition of borosilicate glass

Borosilicate glass consists of approx. 80 % silicon dioxide (SiO2) and approx. 5 - 15 % boron trioxide (B2O3). Other additives are alkali oxides (Na2O, K2O), aluminium oxide (Al2O3) and alkaline earth oxides (CaO, MgO). To increase transparency, borosilicate glass usually has a very low iron content, which causes the green colour typical of window glass .

Properties

Due to its boron content, borosilicate glass has a significantly higher chemical stability against water, many chemicals and pharmaceutical products compared to window glass. In addition, borosilicate glass has a significantly higher thermal stability against temperature fluctuations due to its coefficient of thermal expansion, which is less than half that of window glass.

Production of glass wafers

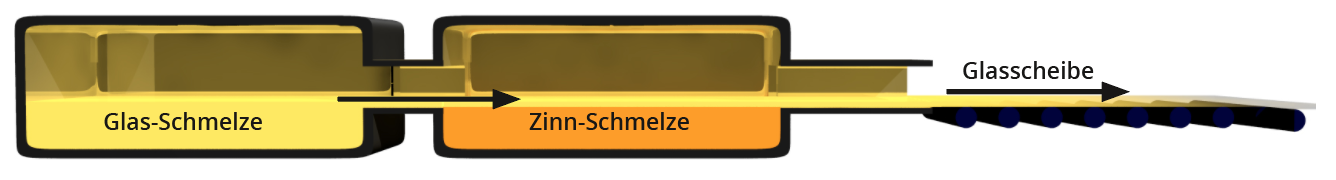

Borosilicate glass intended for further processing into glass wafers is produced using the "float process". In this process, molten glass is allowed to flow continuously from a melting furnace over a bath of molten tin, where it is evenly distributed and brought to the desired thickness. On the other side of the tin bath, the now solidified glass is lifted from the tin surface, cooled to minimise stress and cut to the desired dimensions.

The manufacture of glass panes from borosilicate glass using the "float process".

Specifications of glass wafers

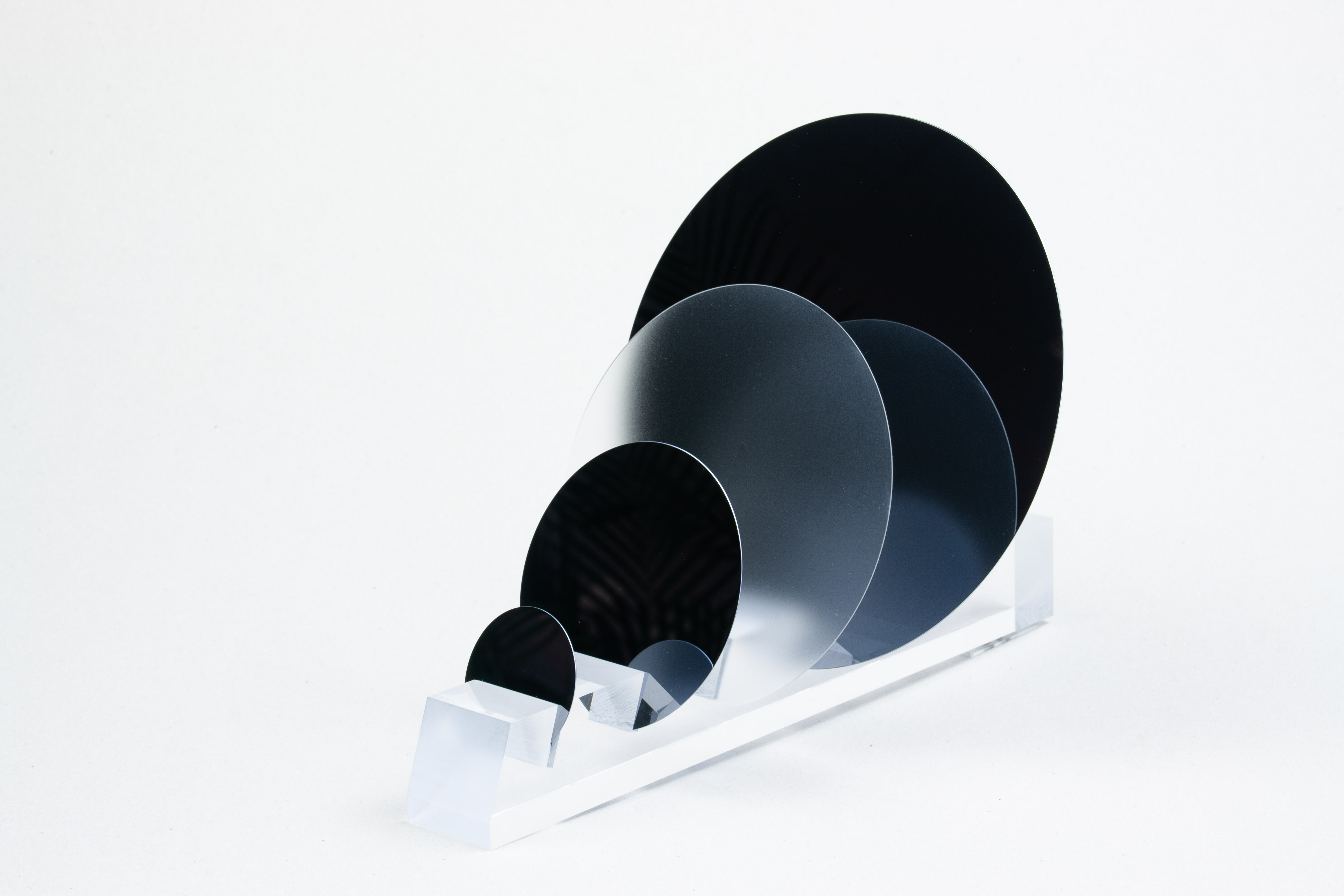

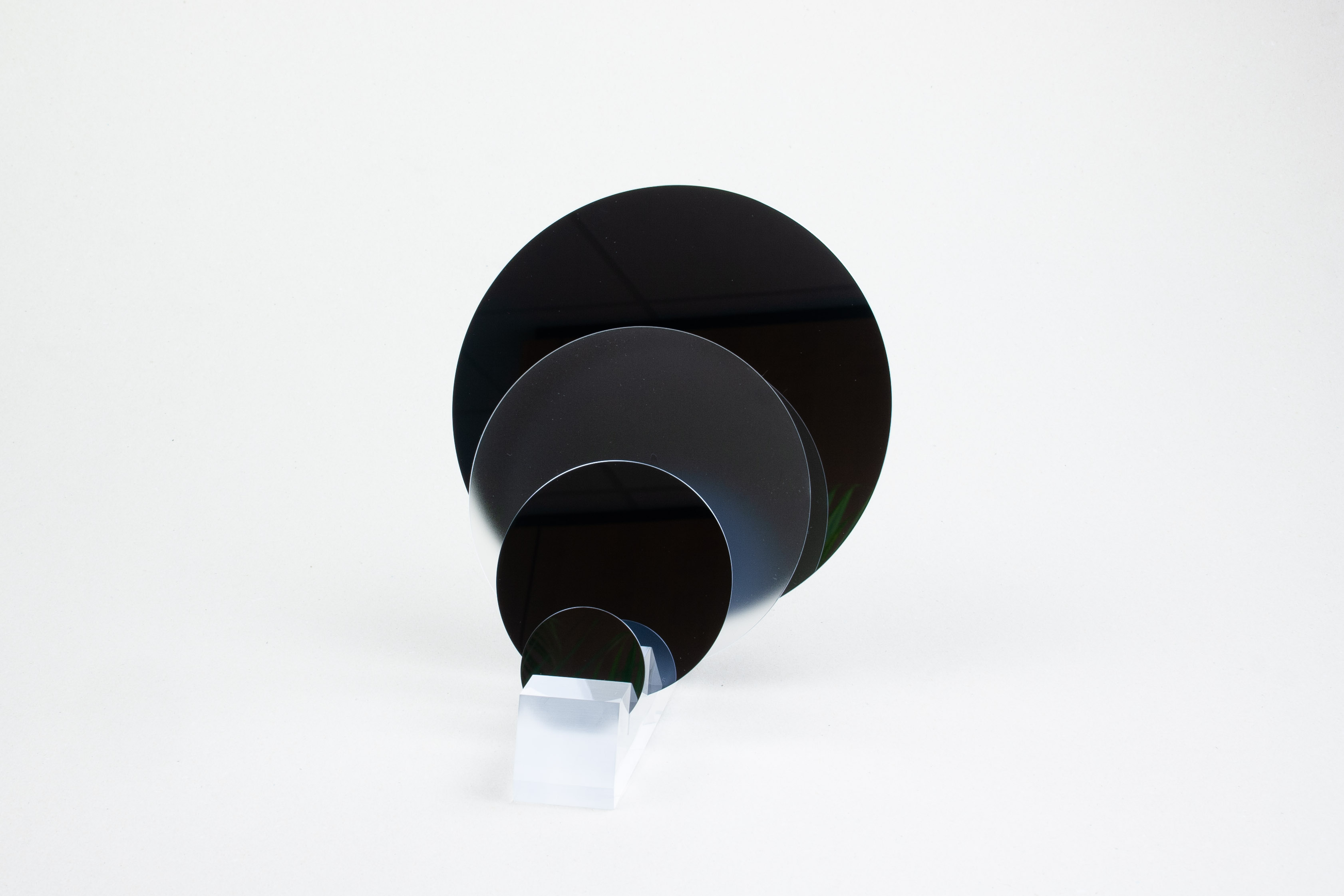

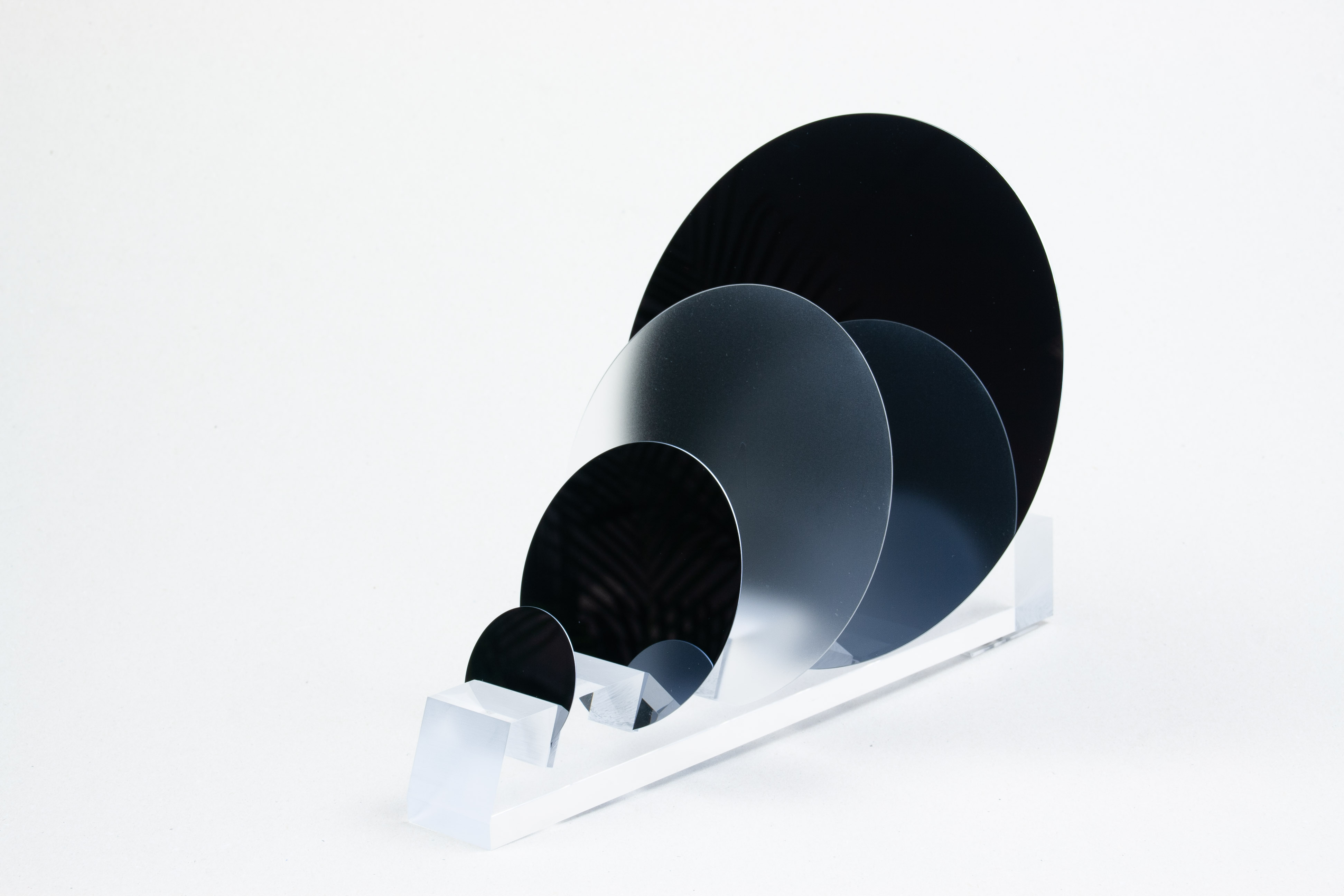

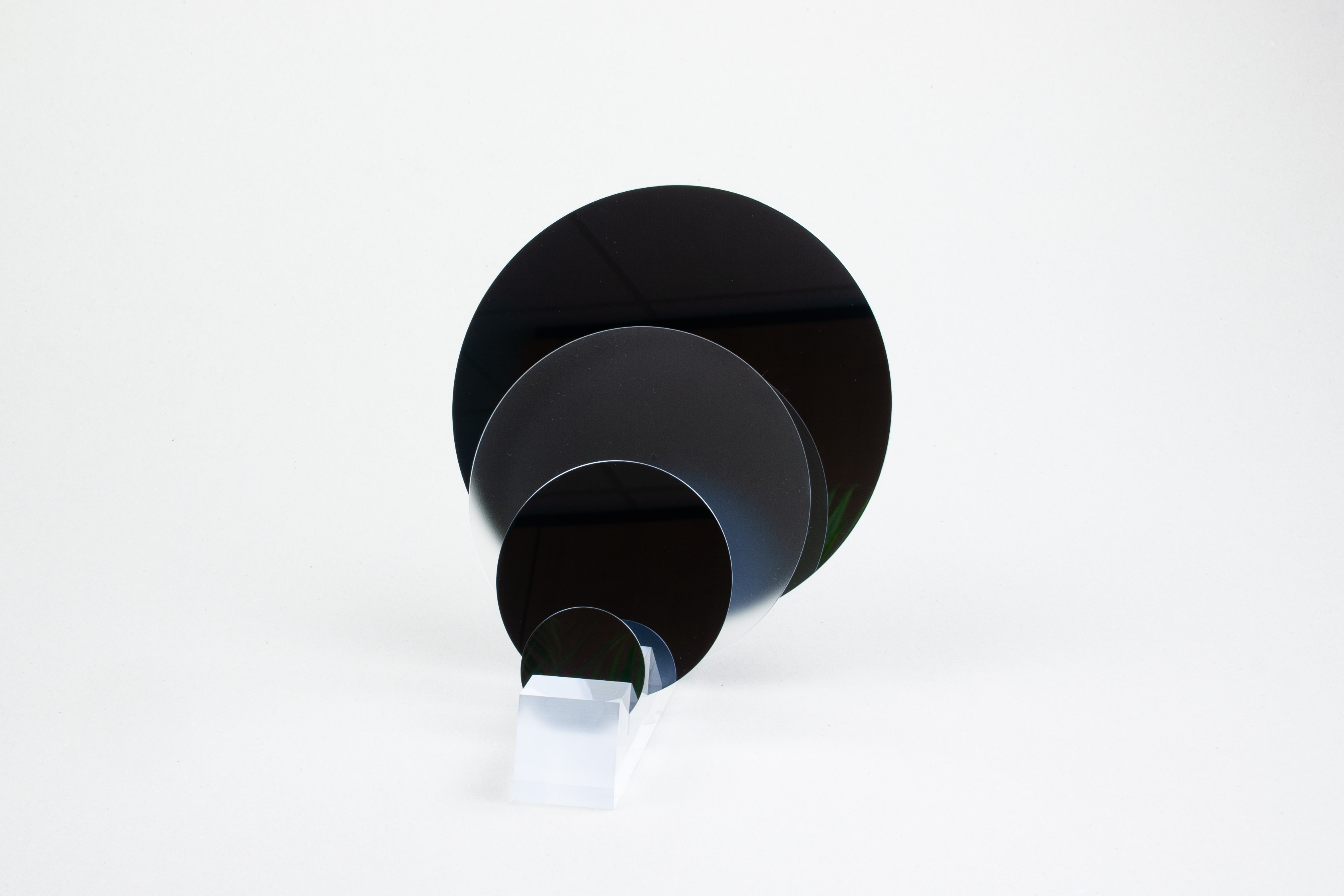

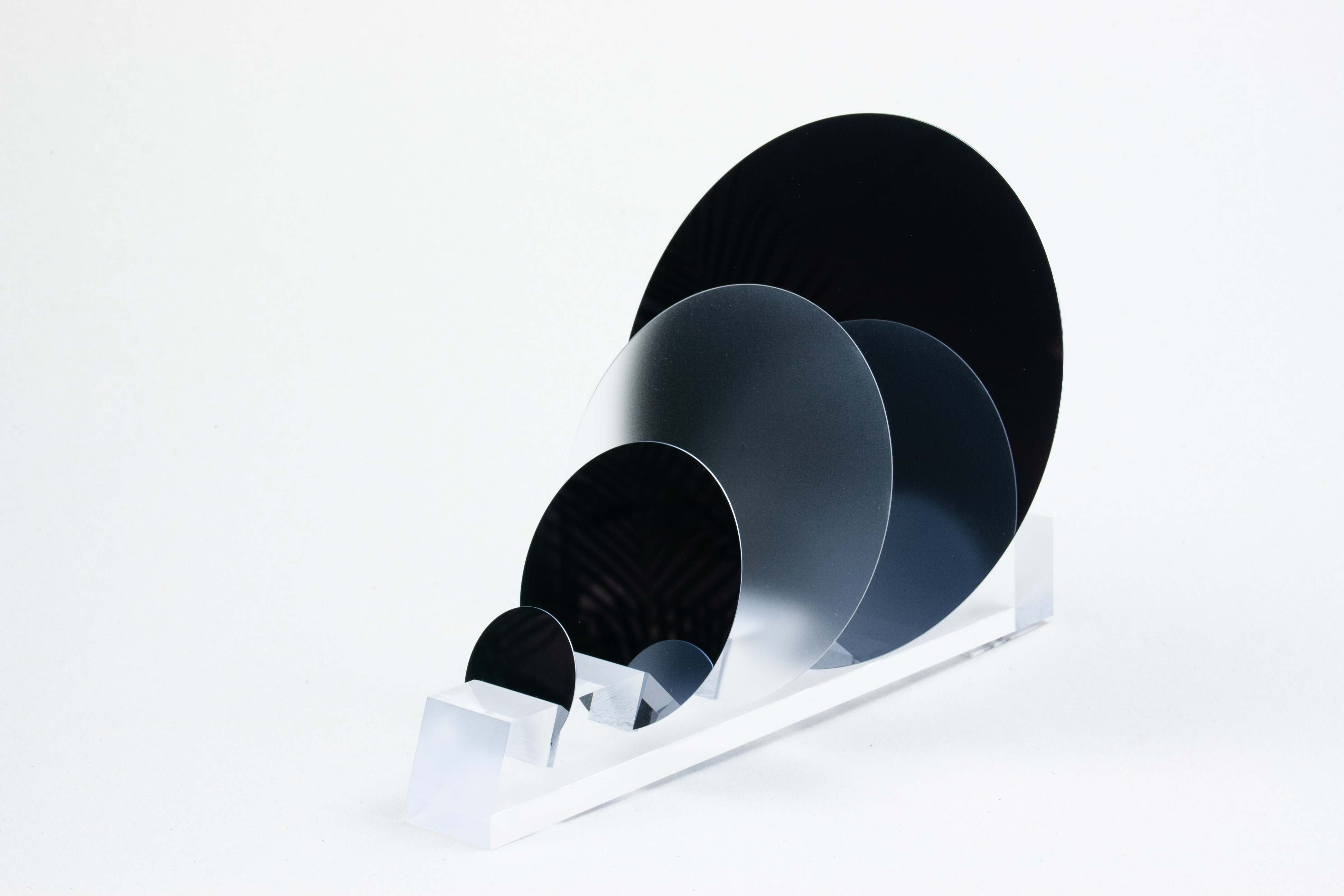

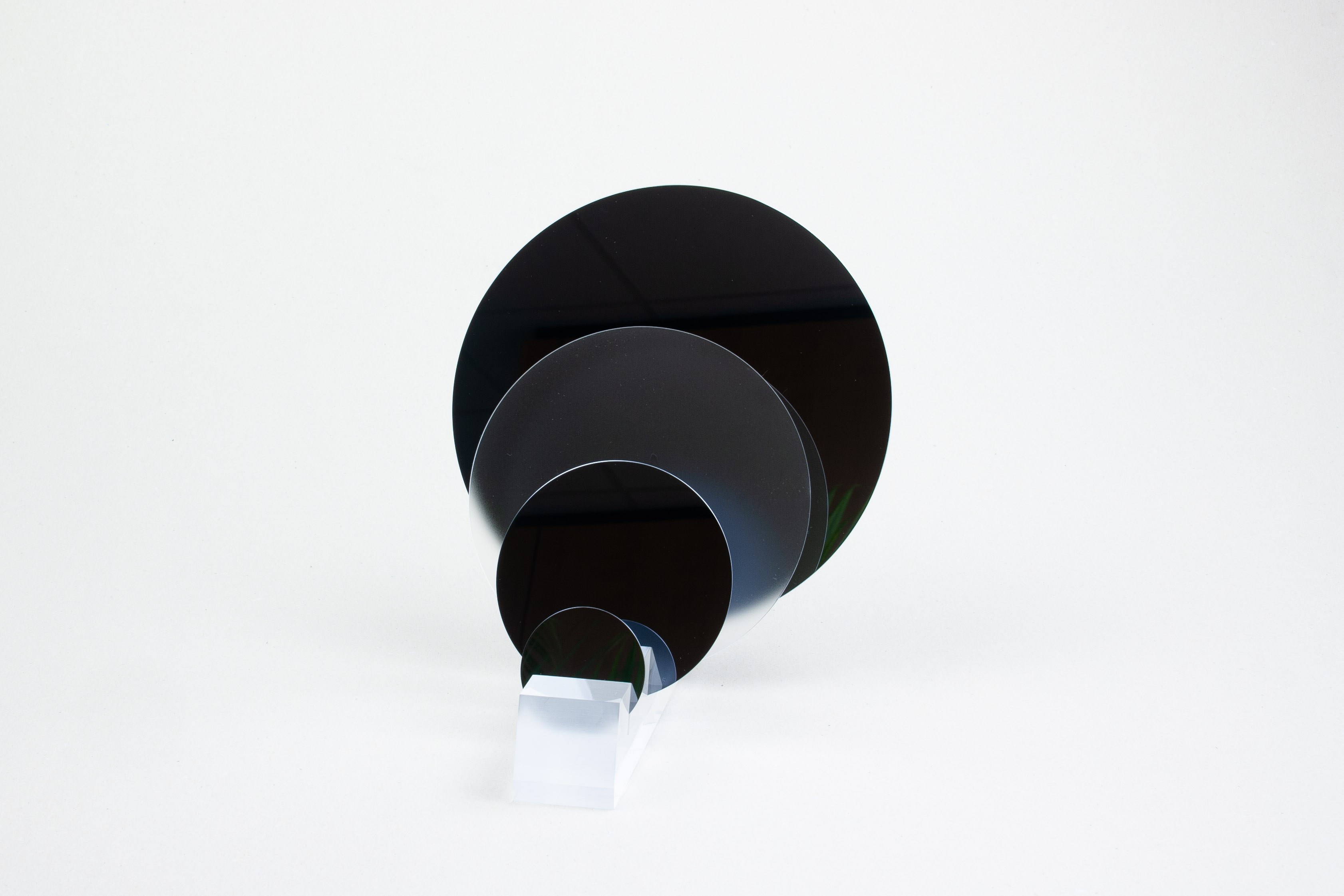

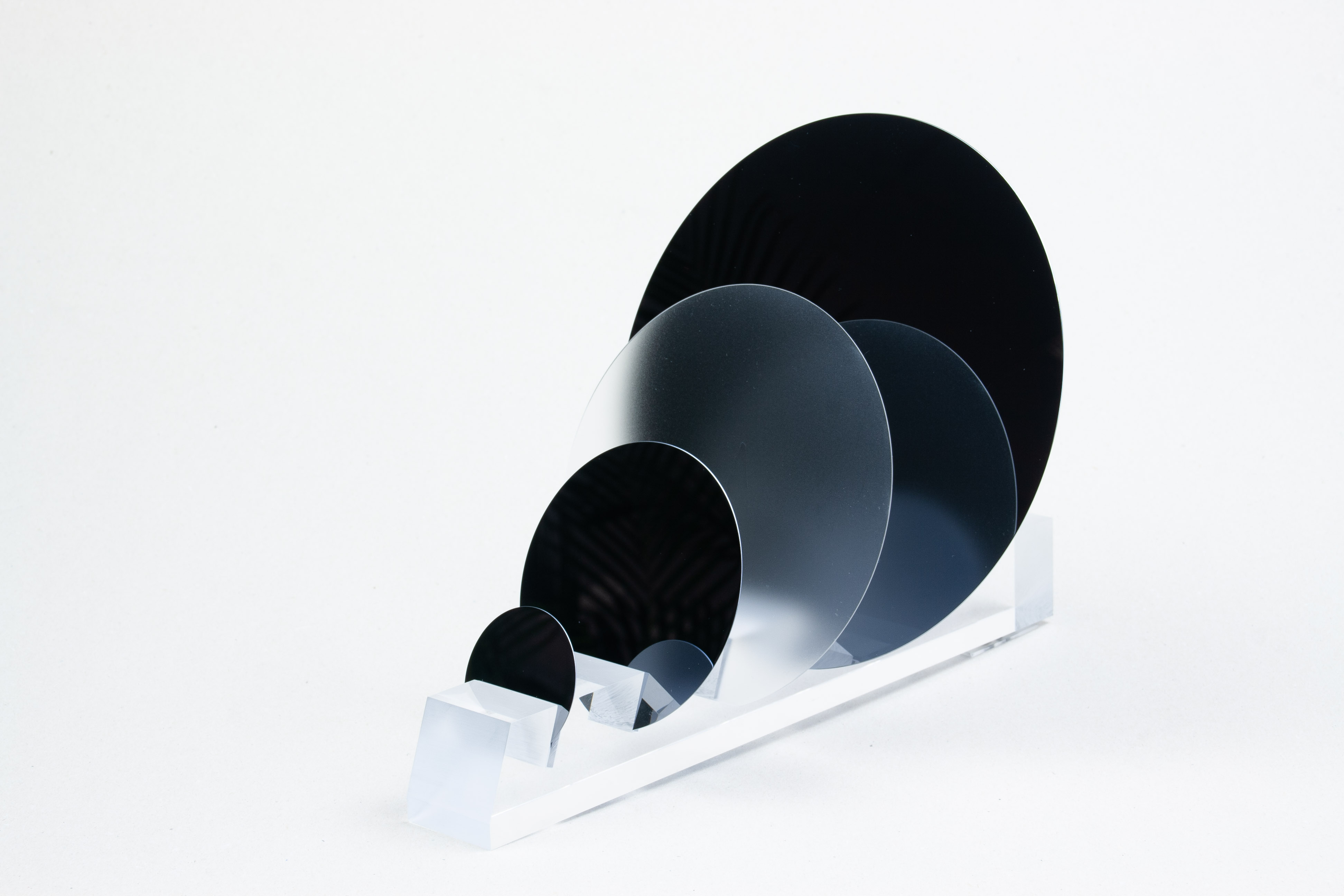

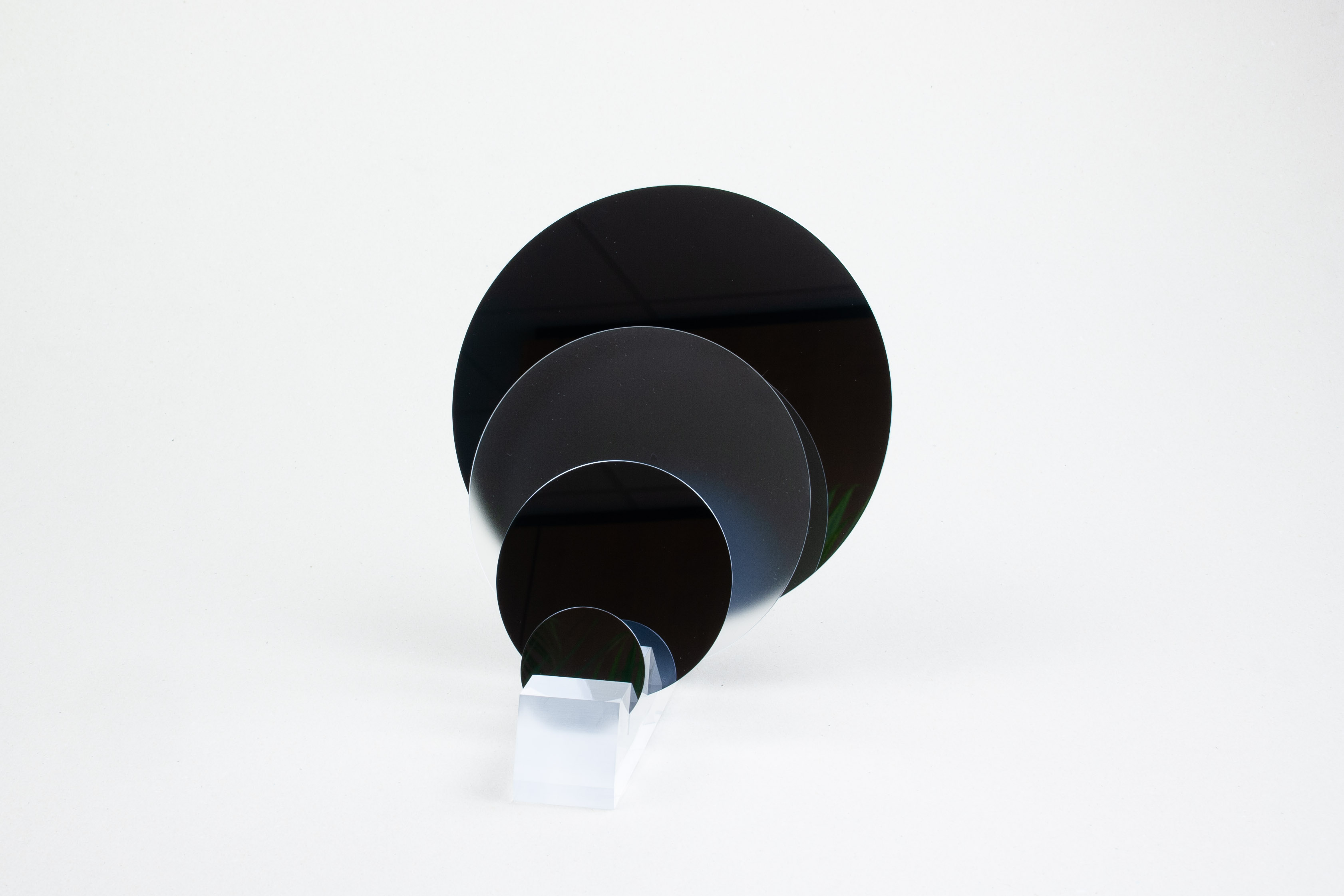

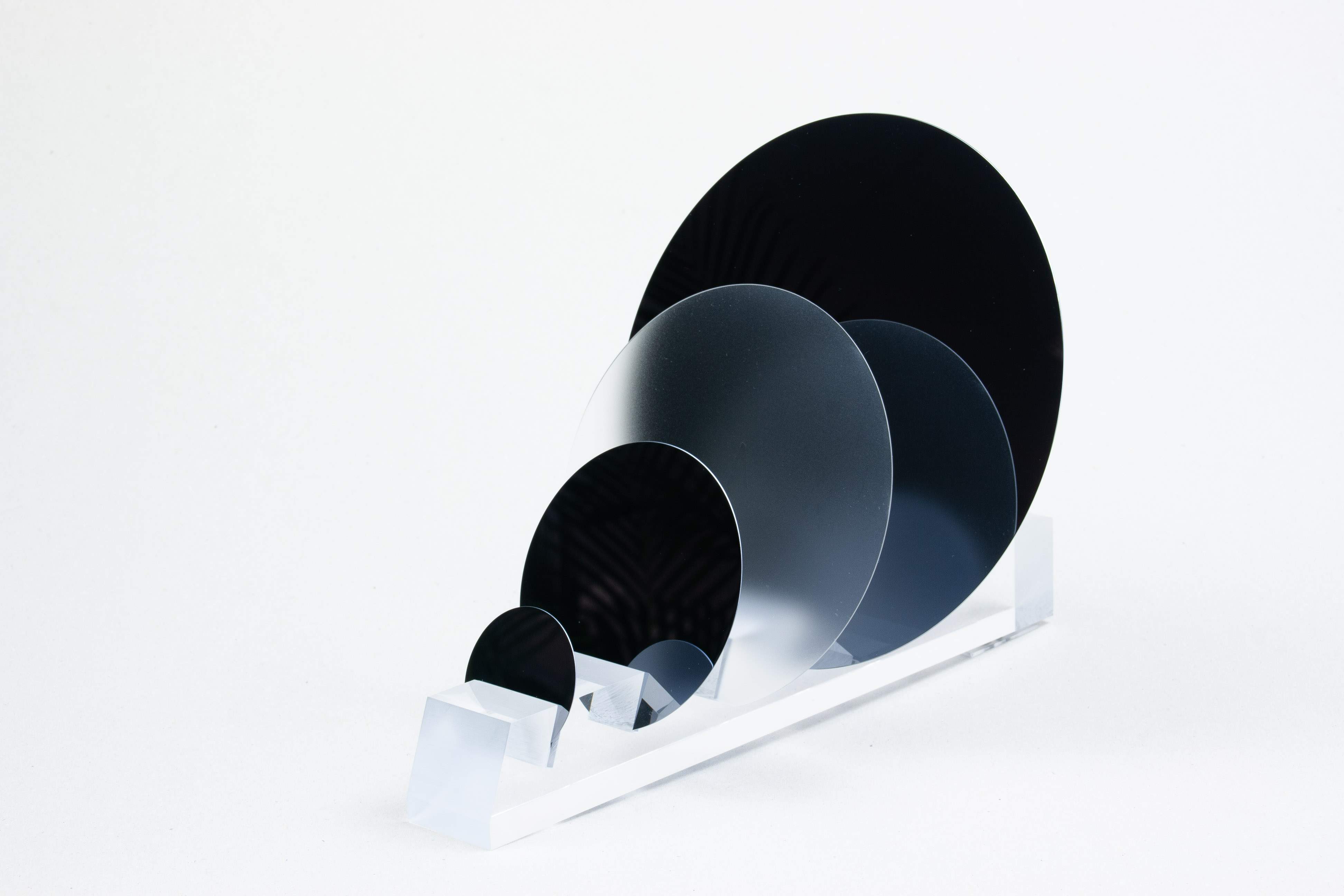

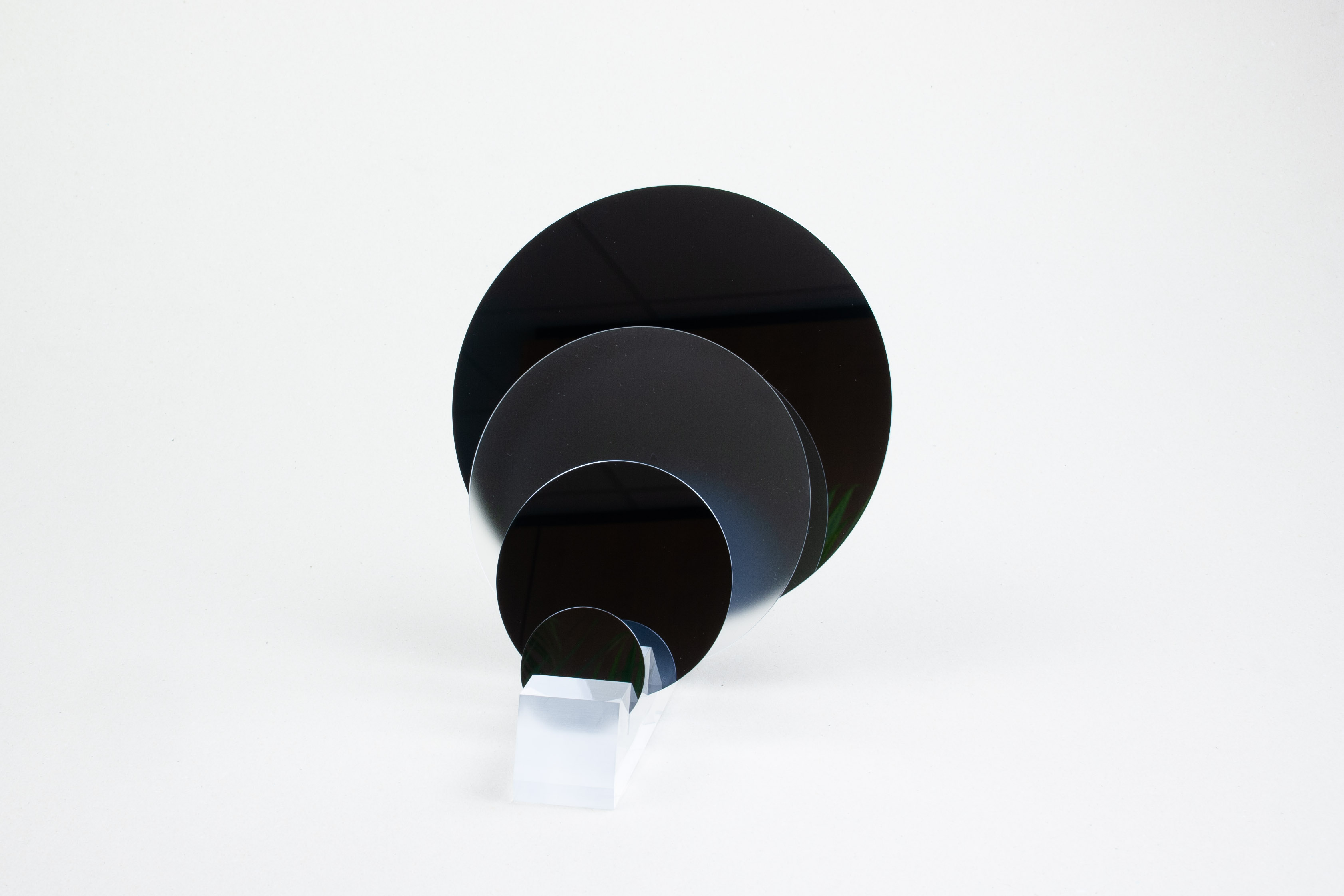

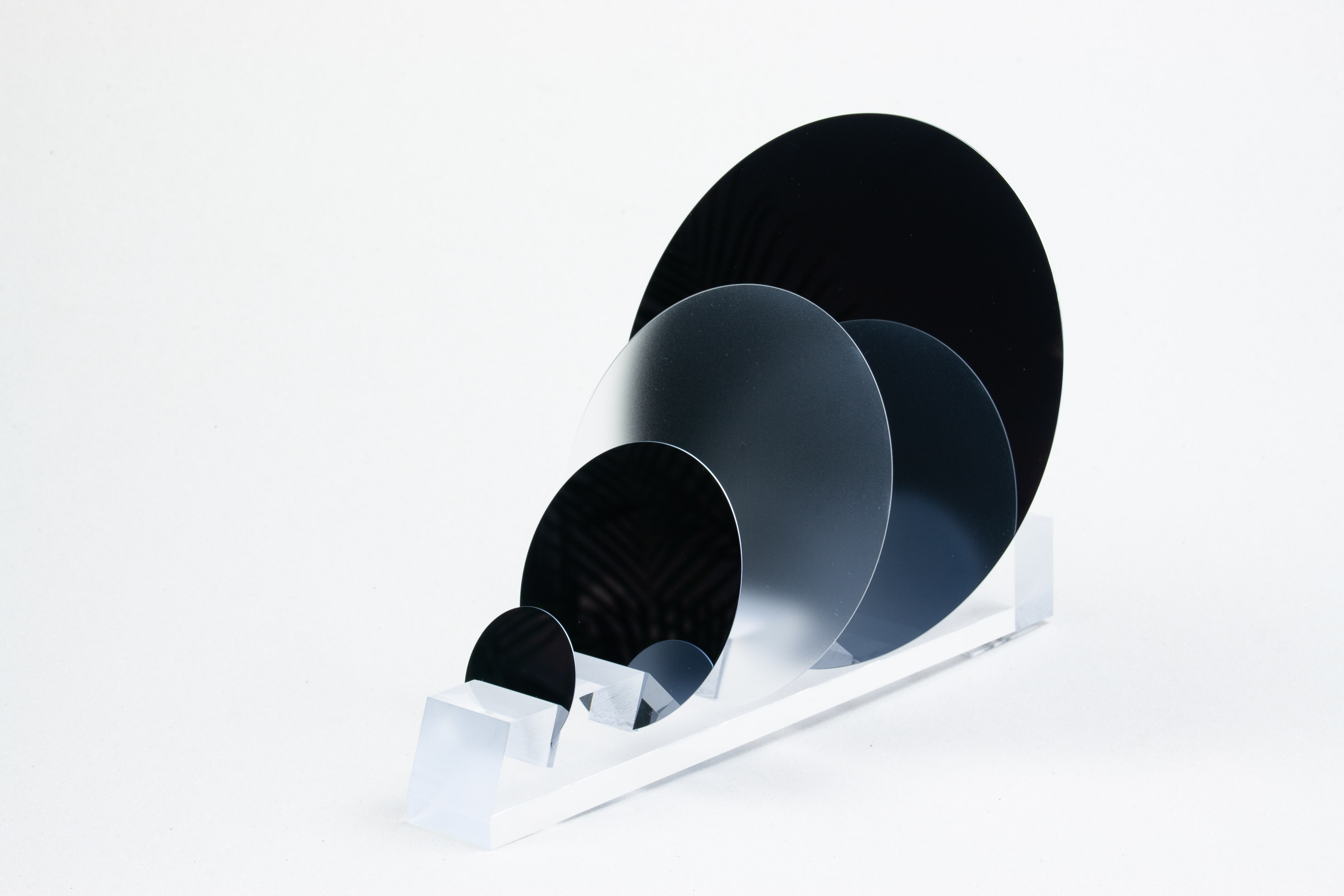

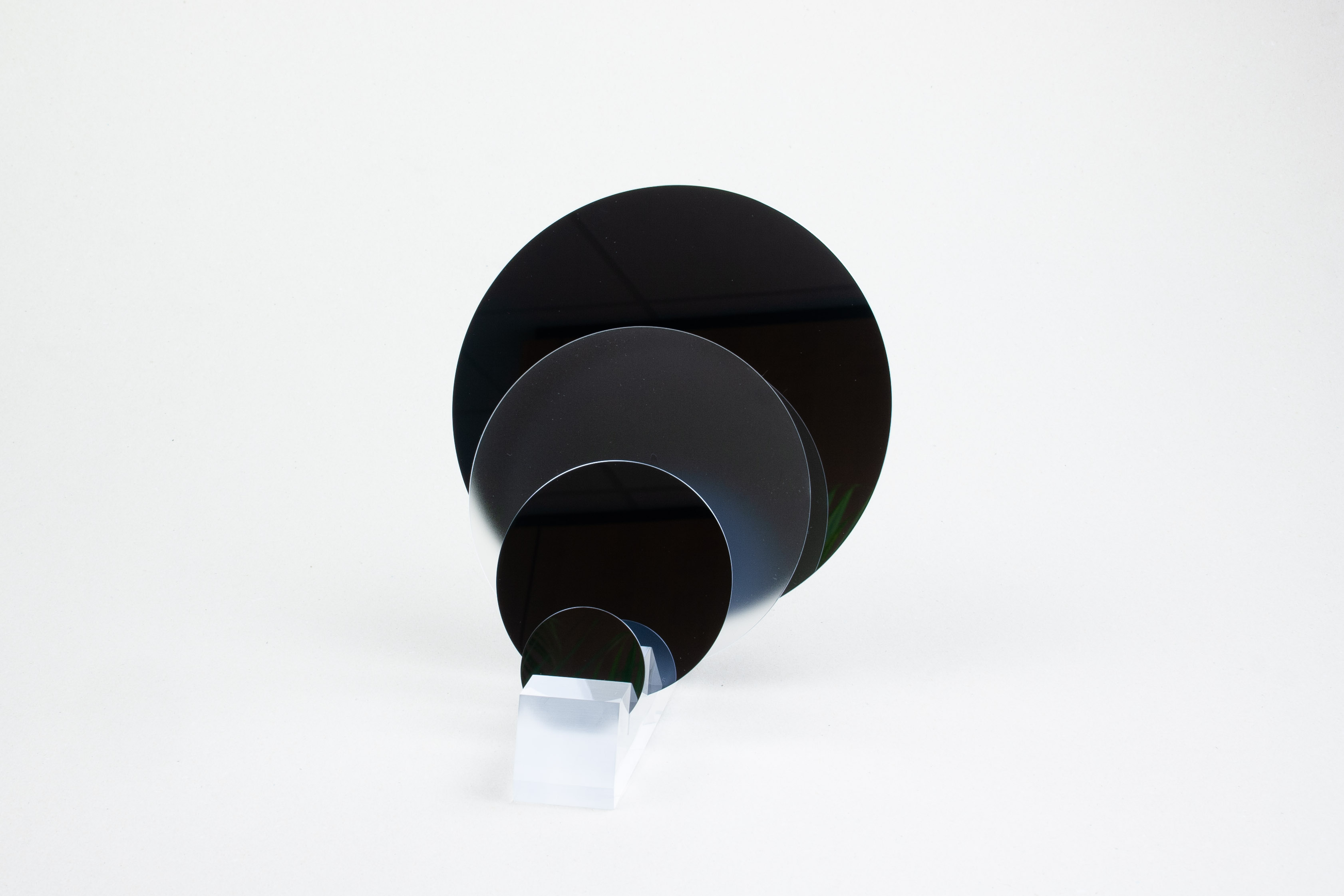

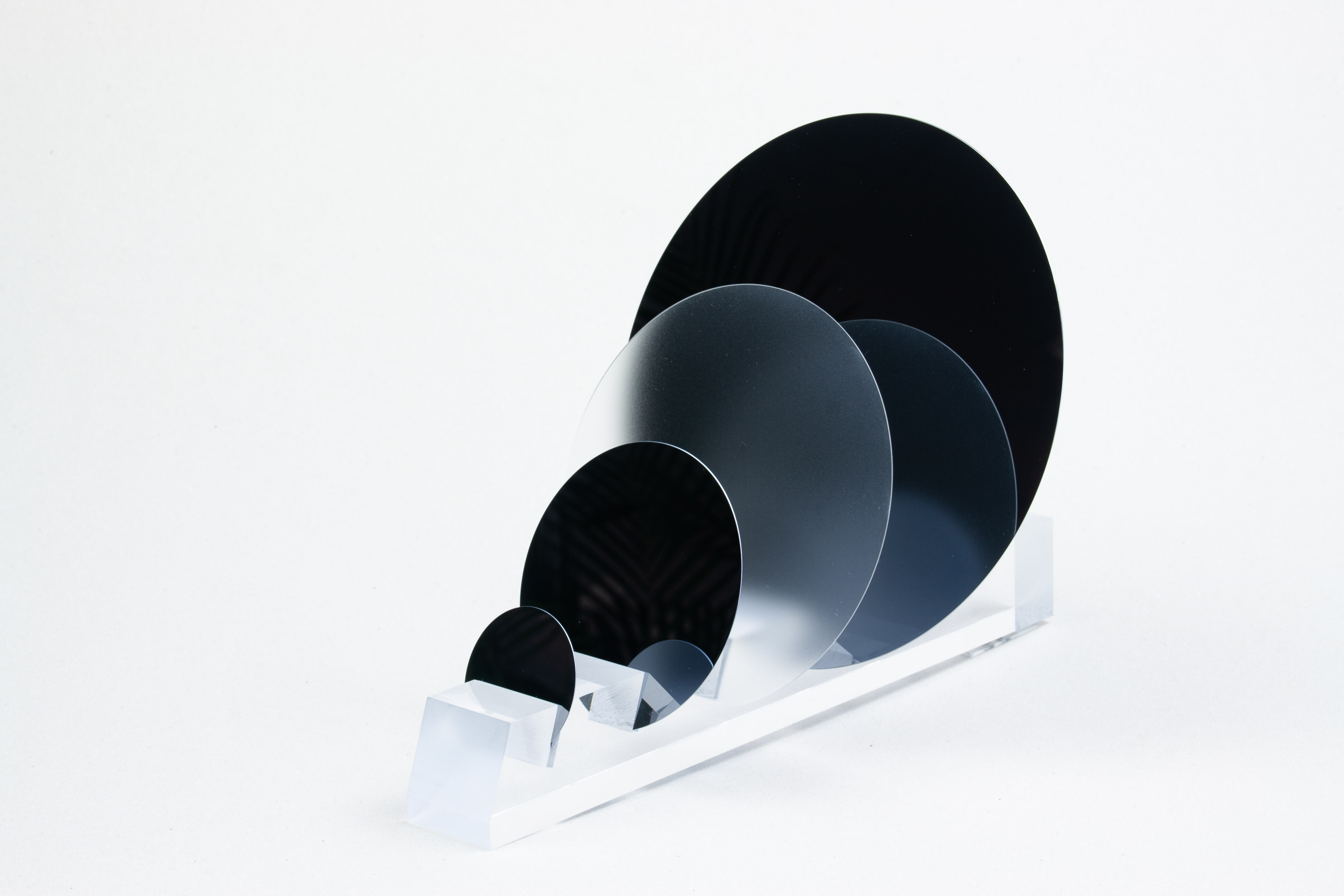

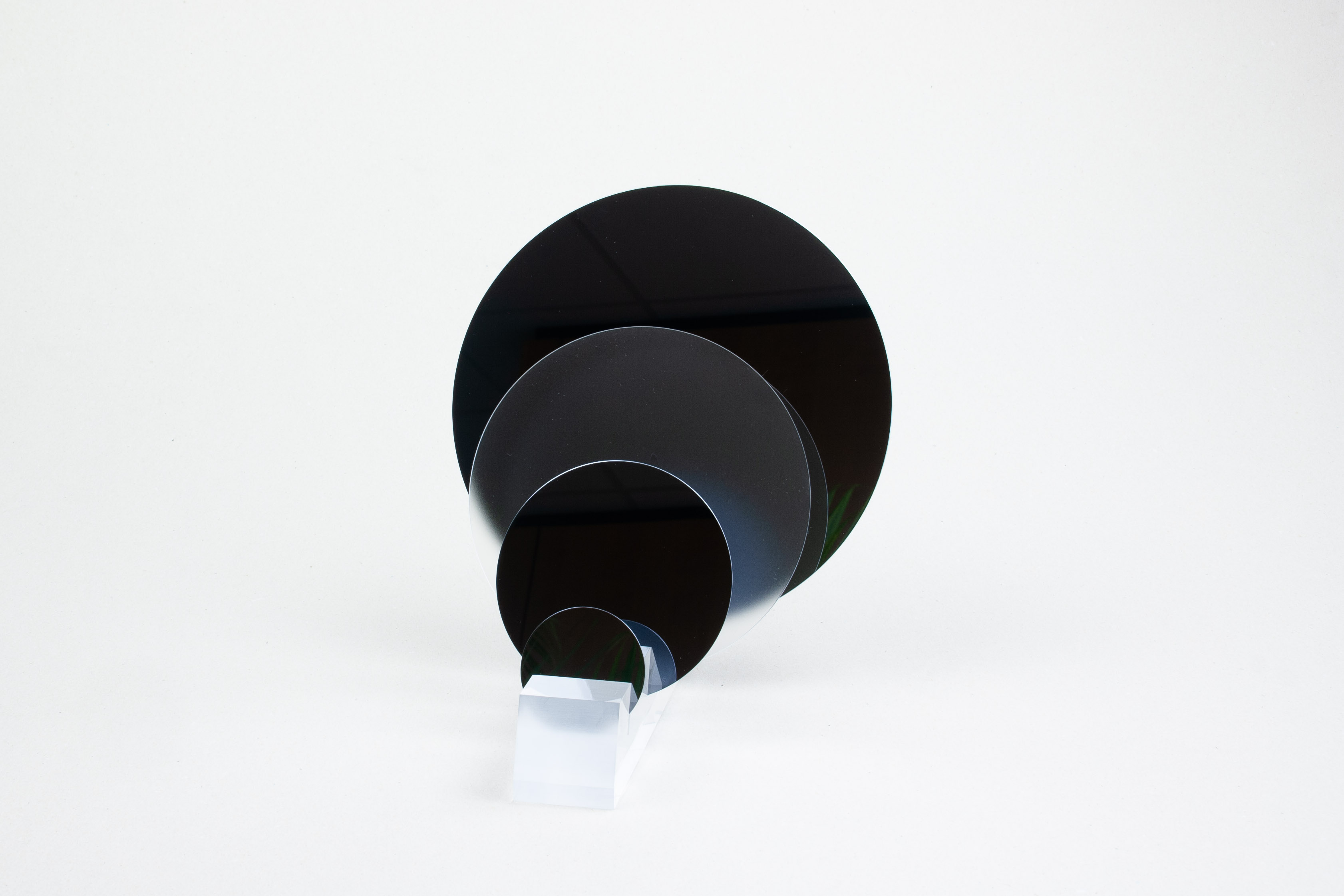

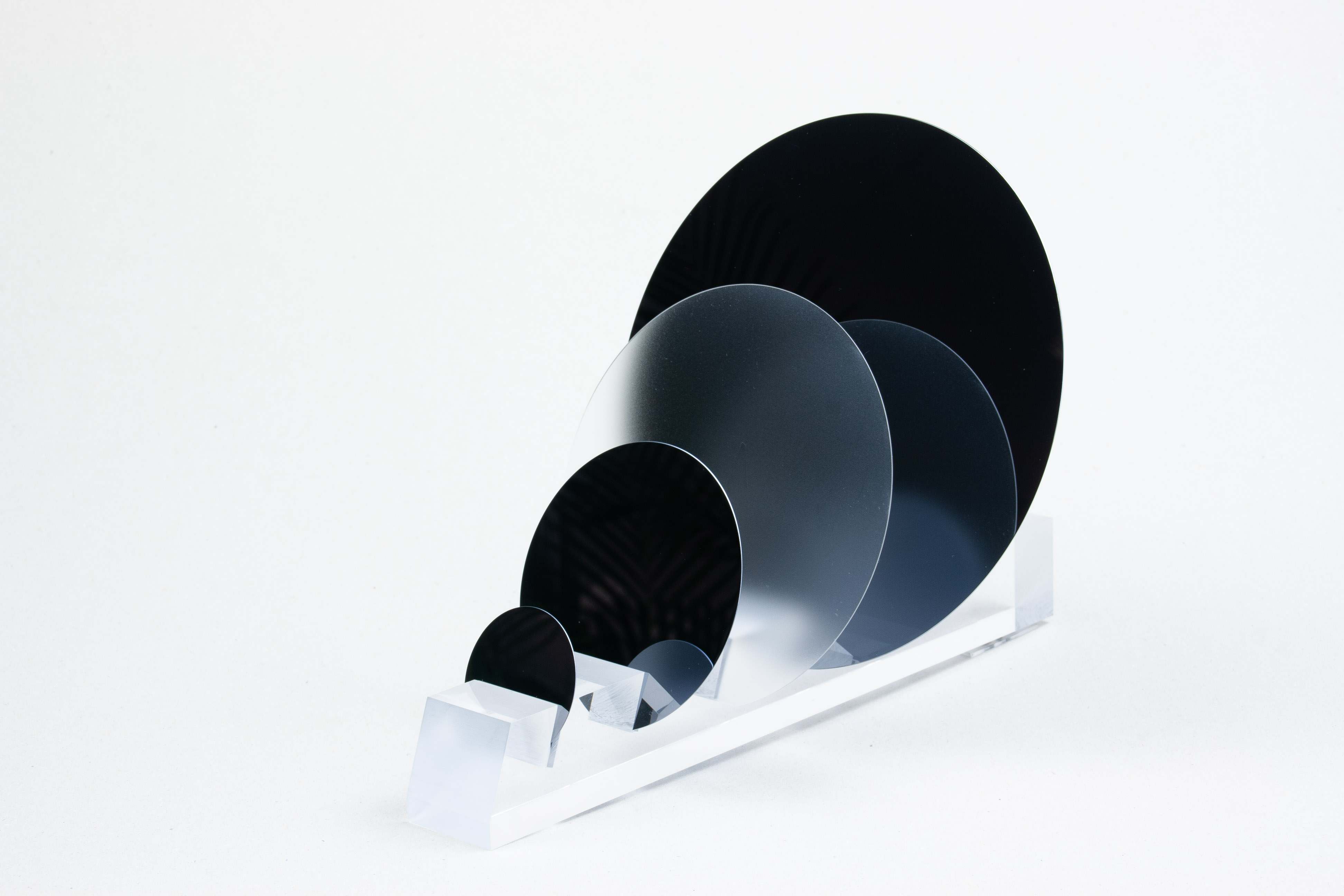

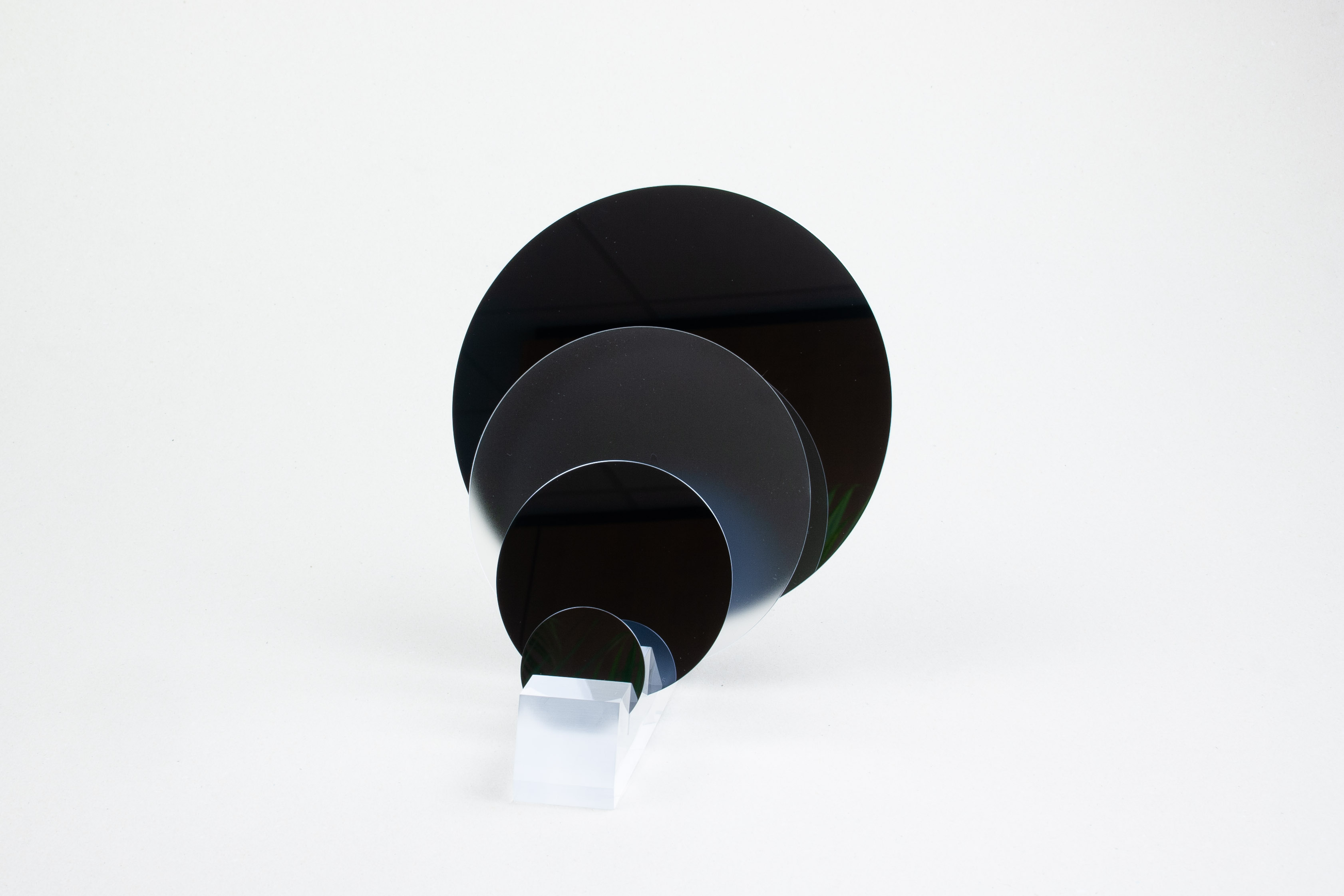

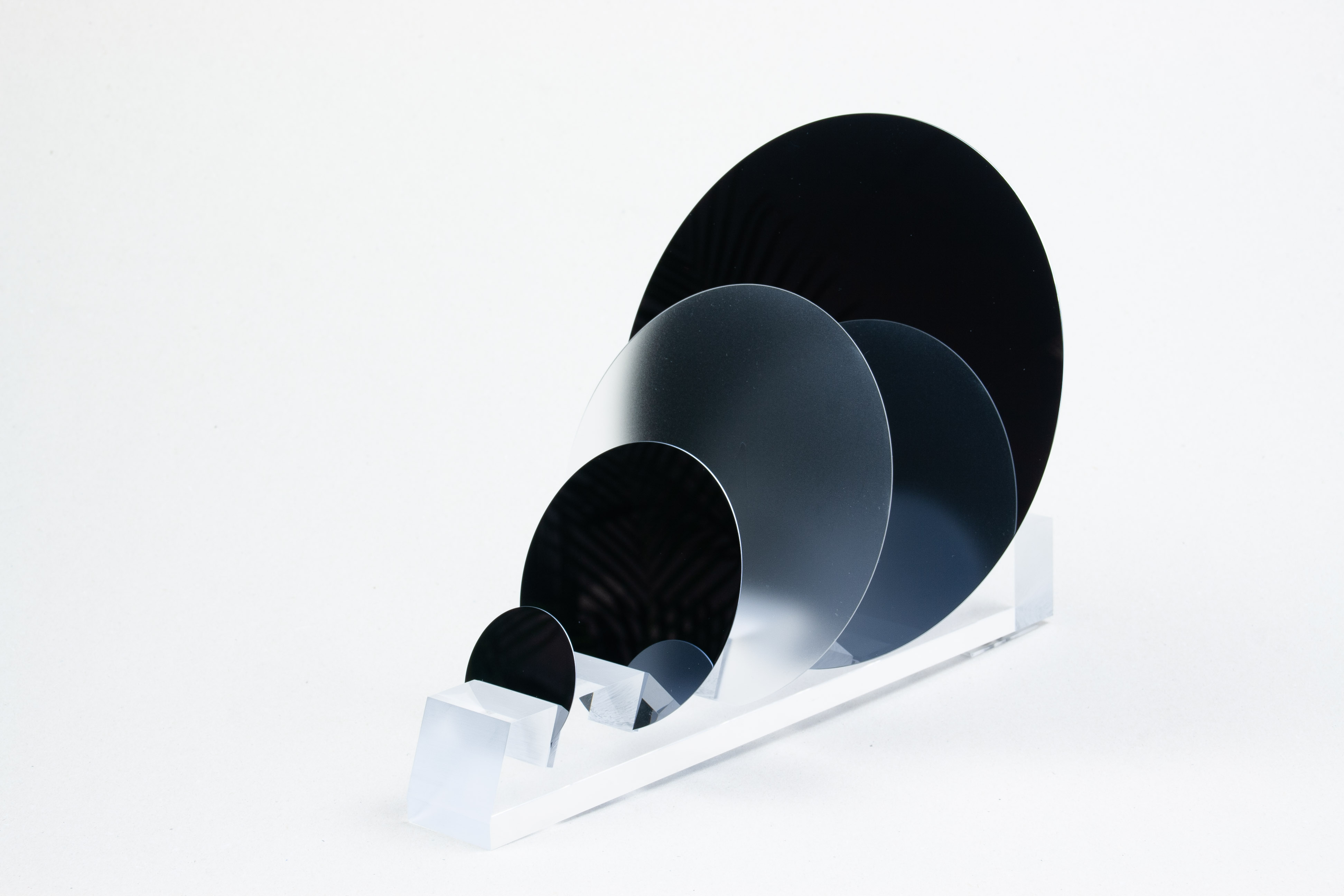

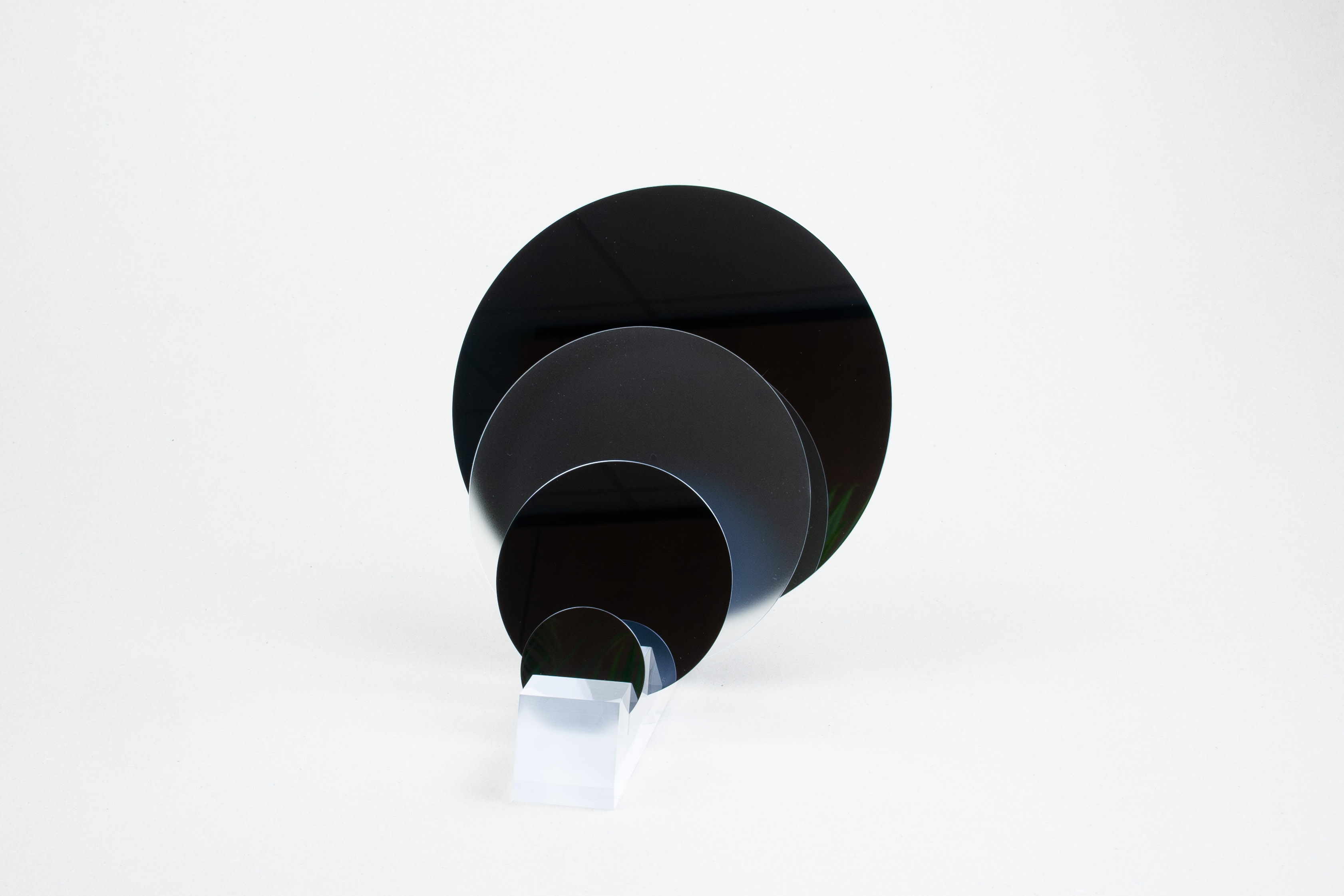

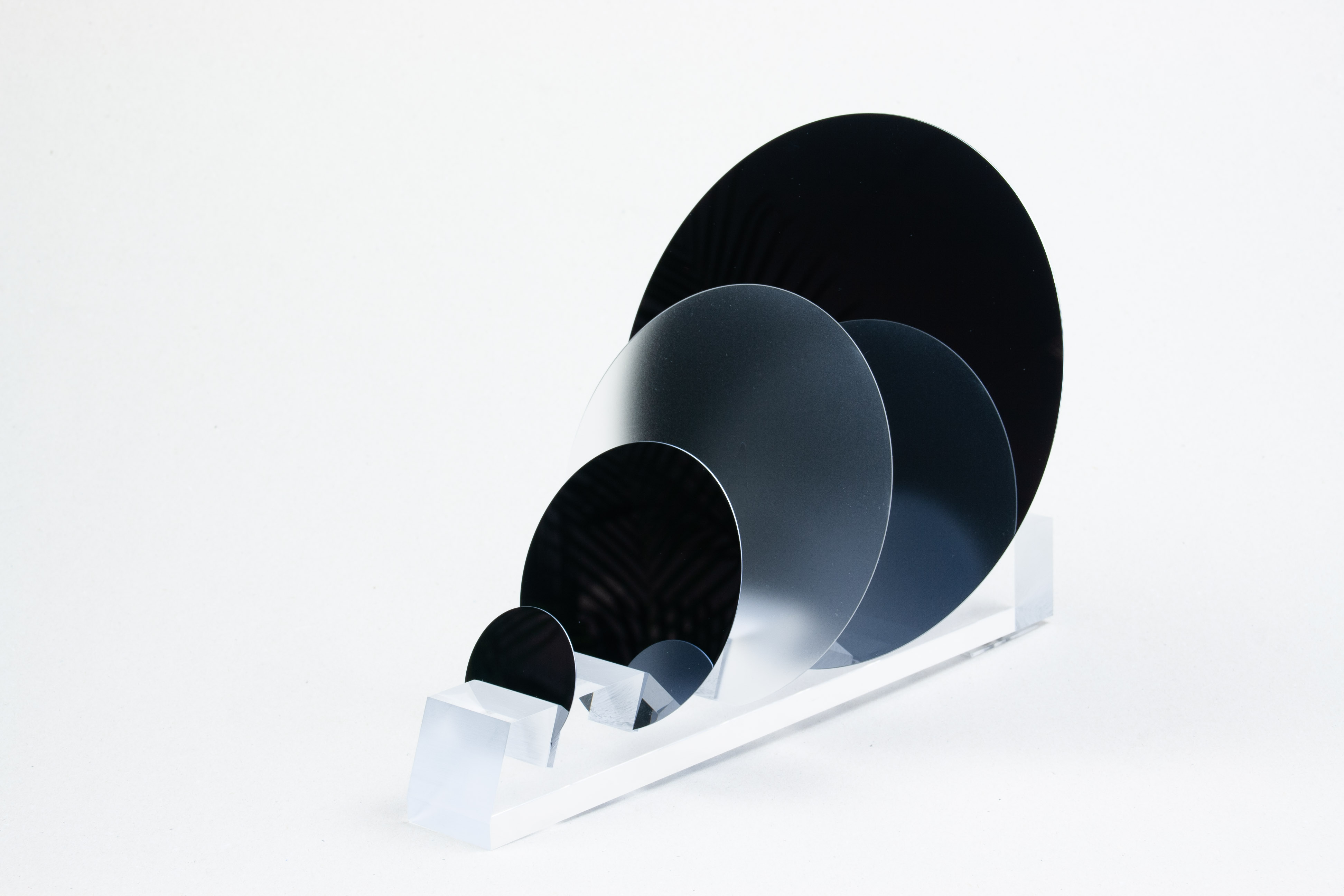

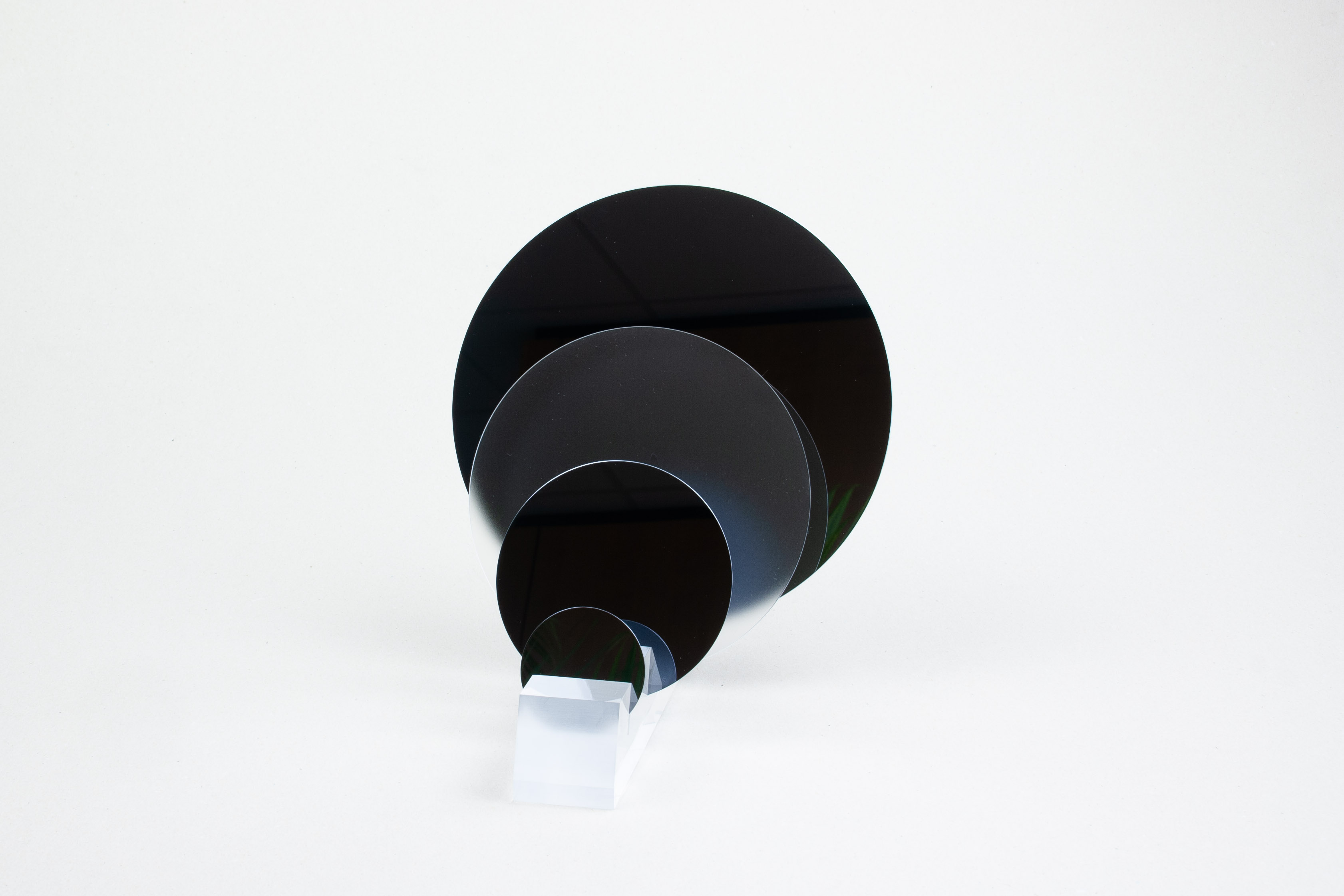

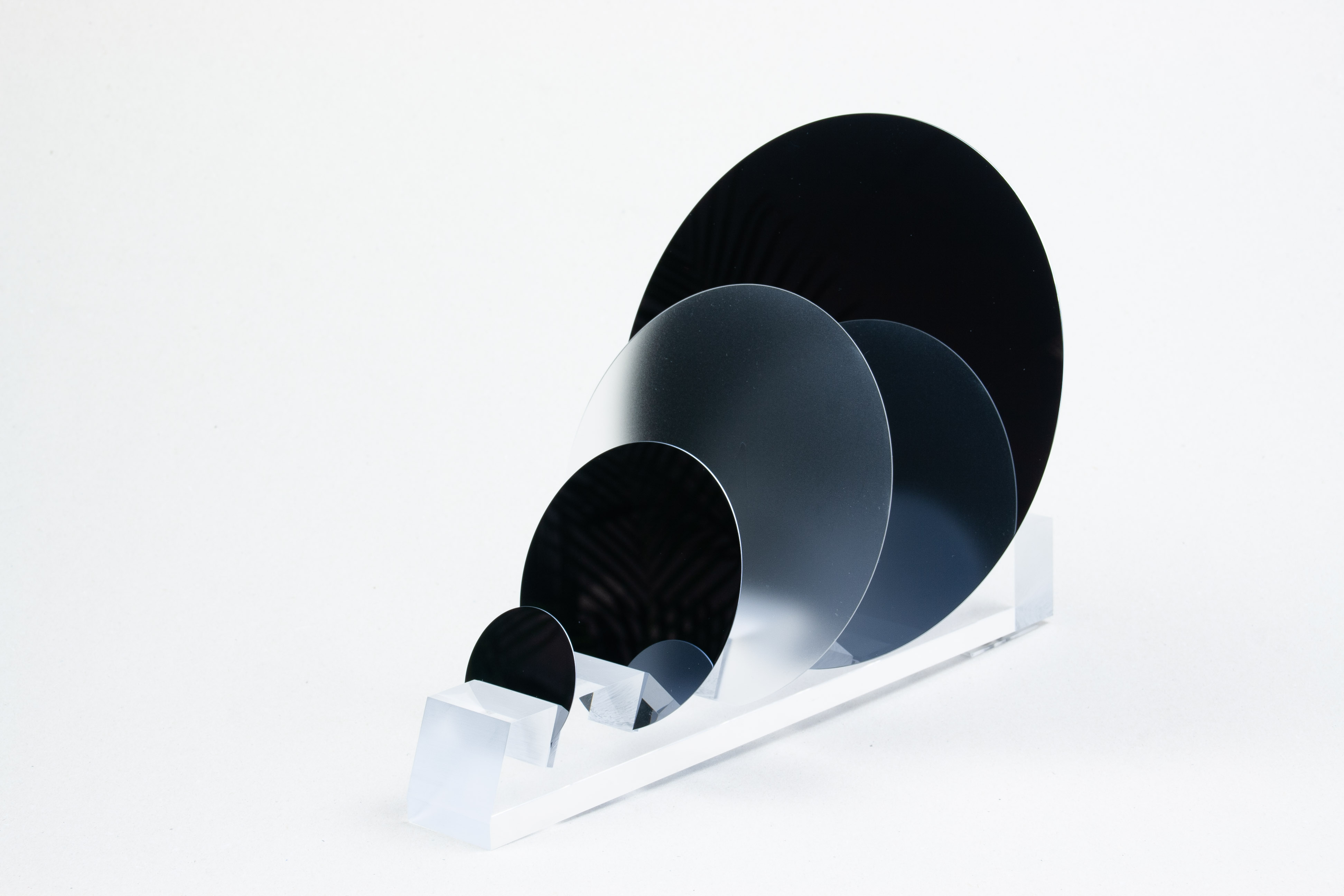

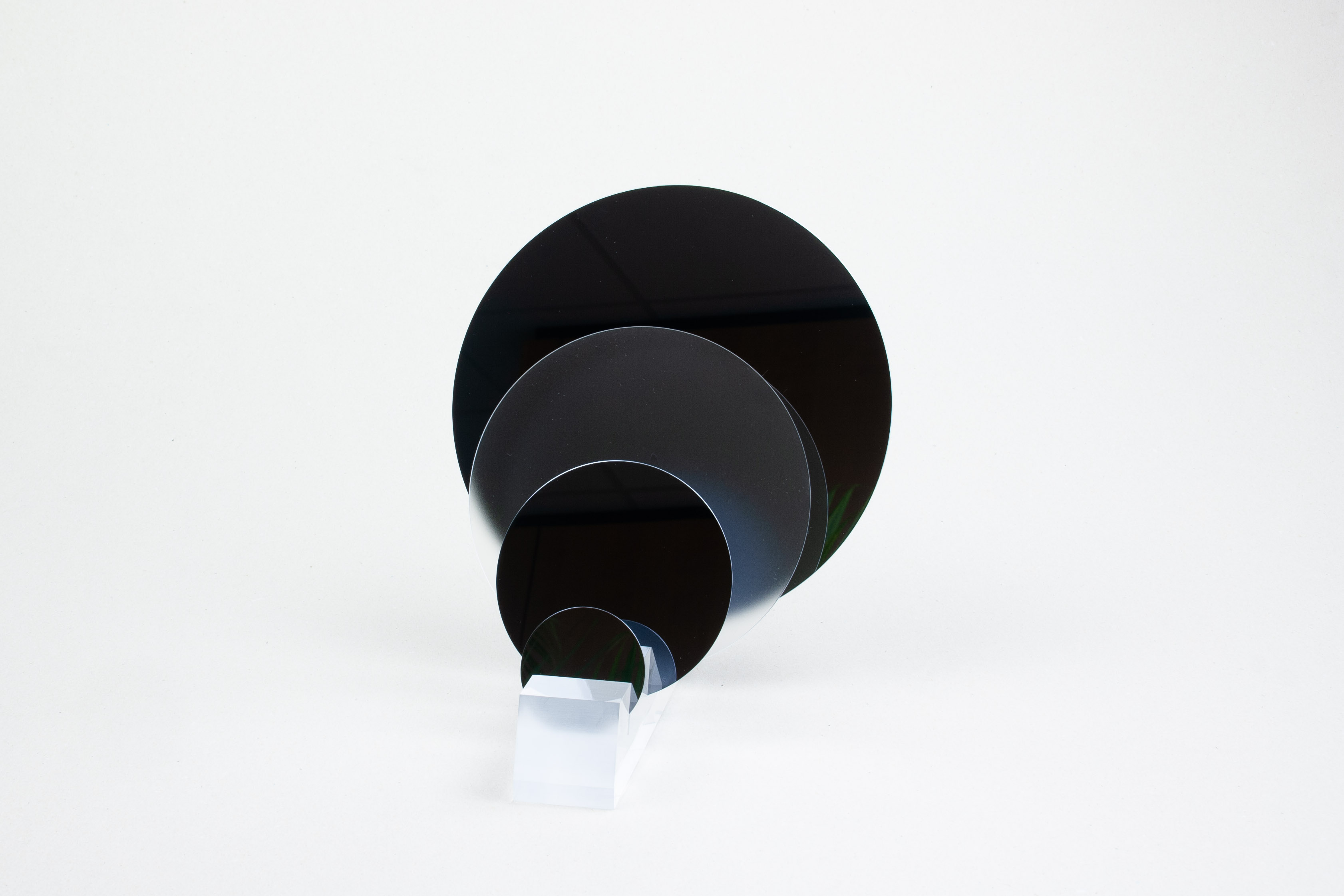

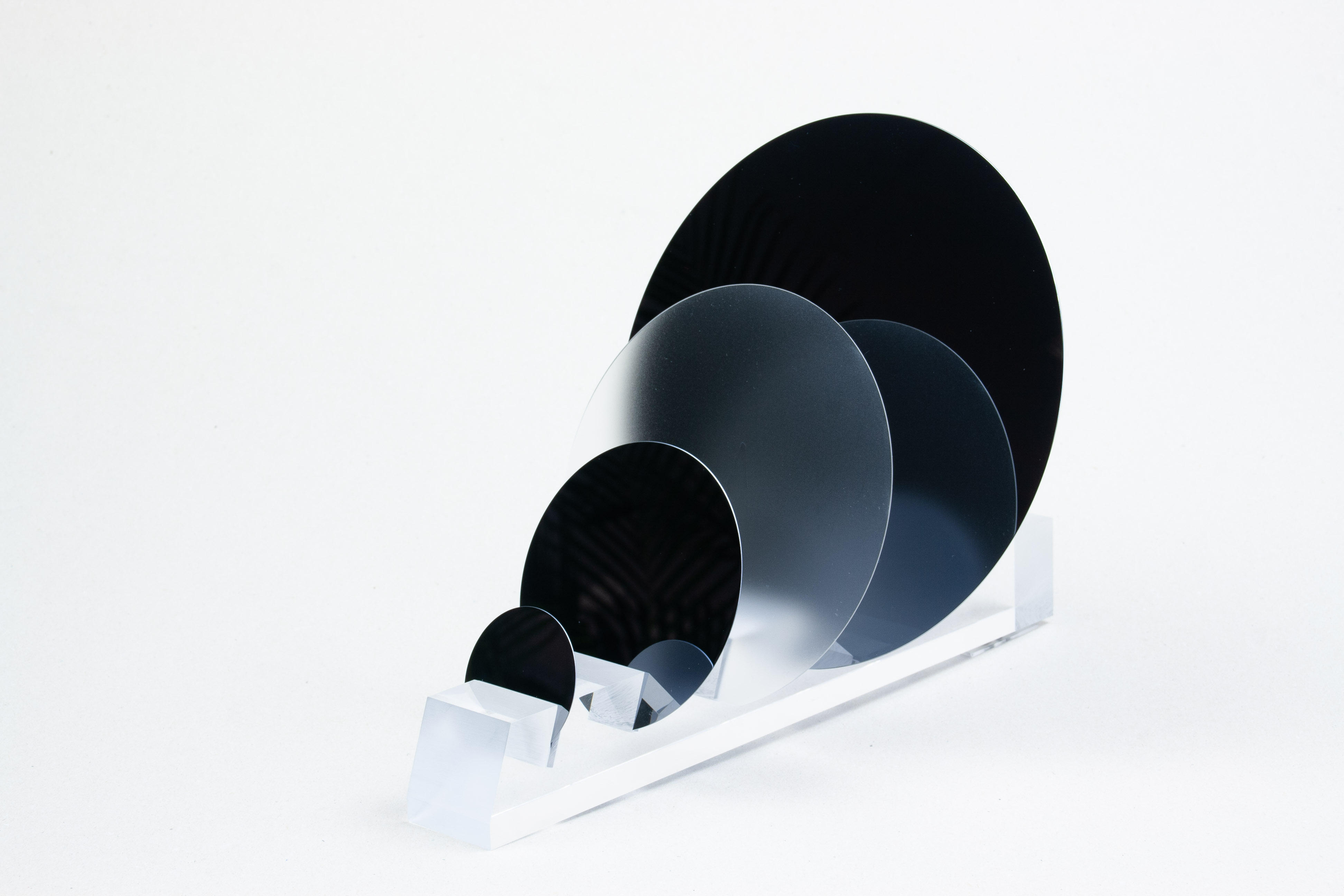

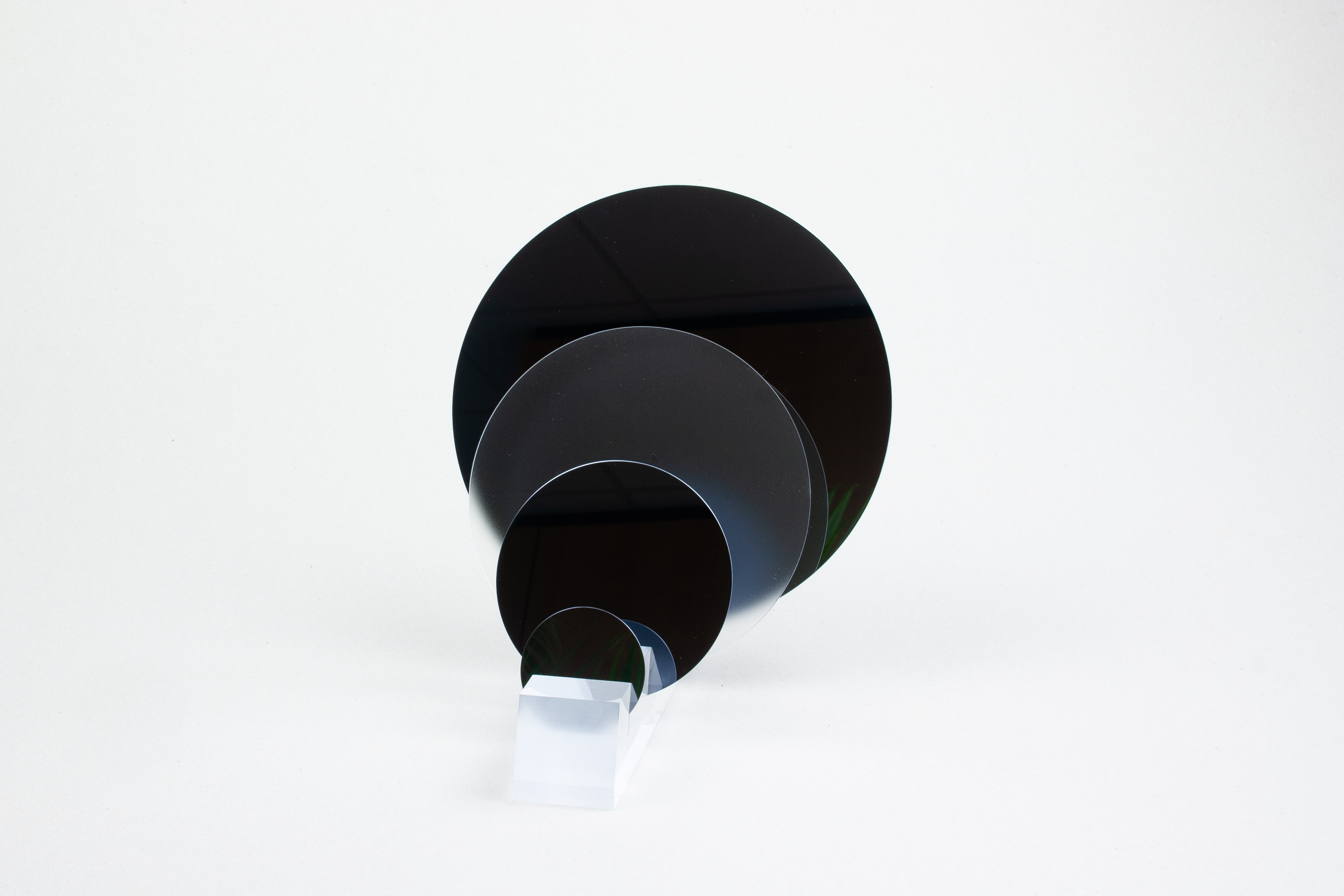

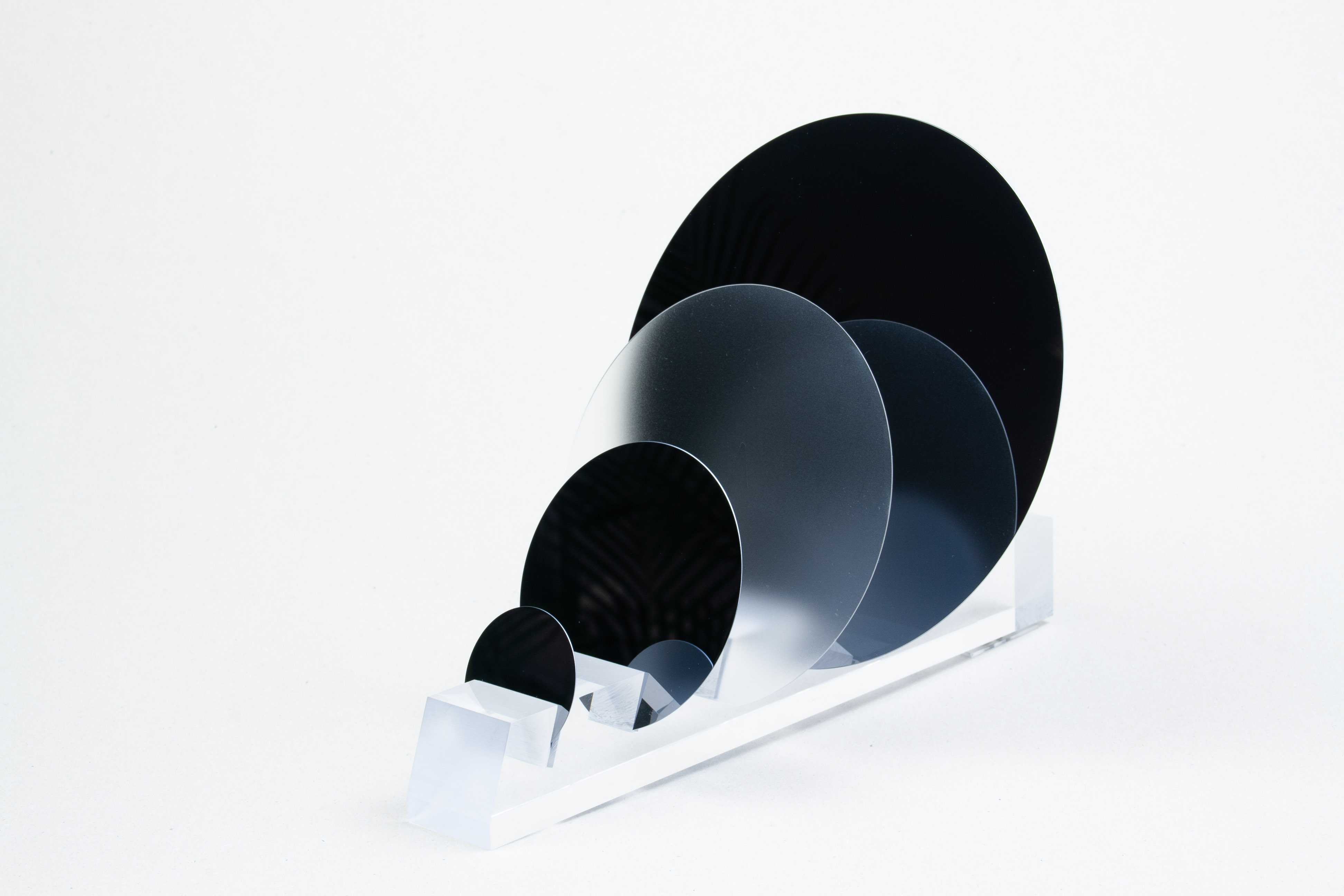

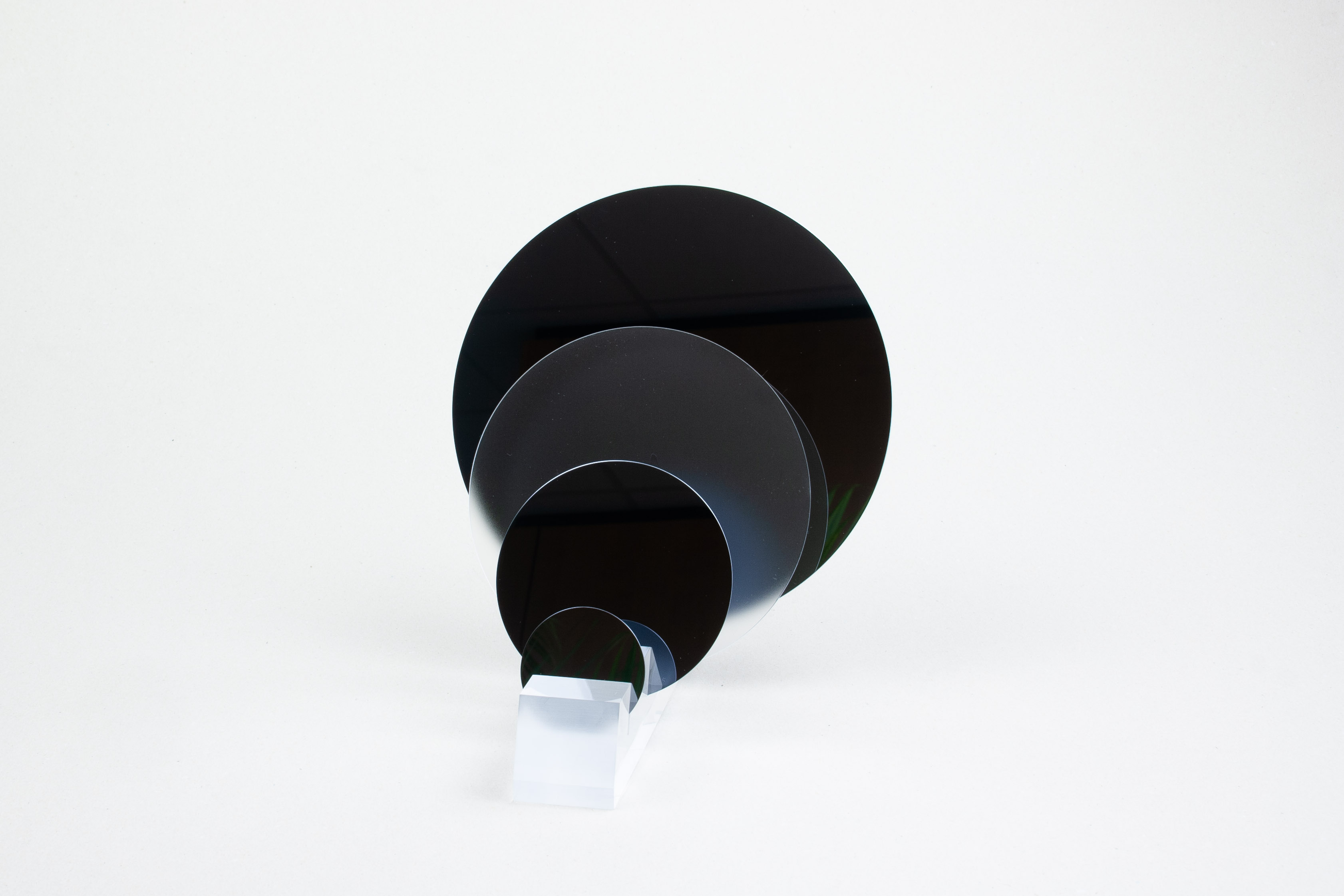

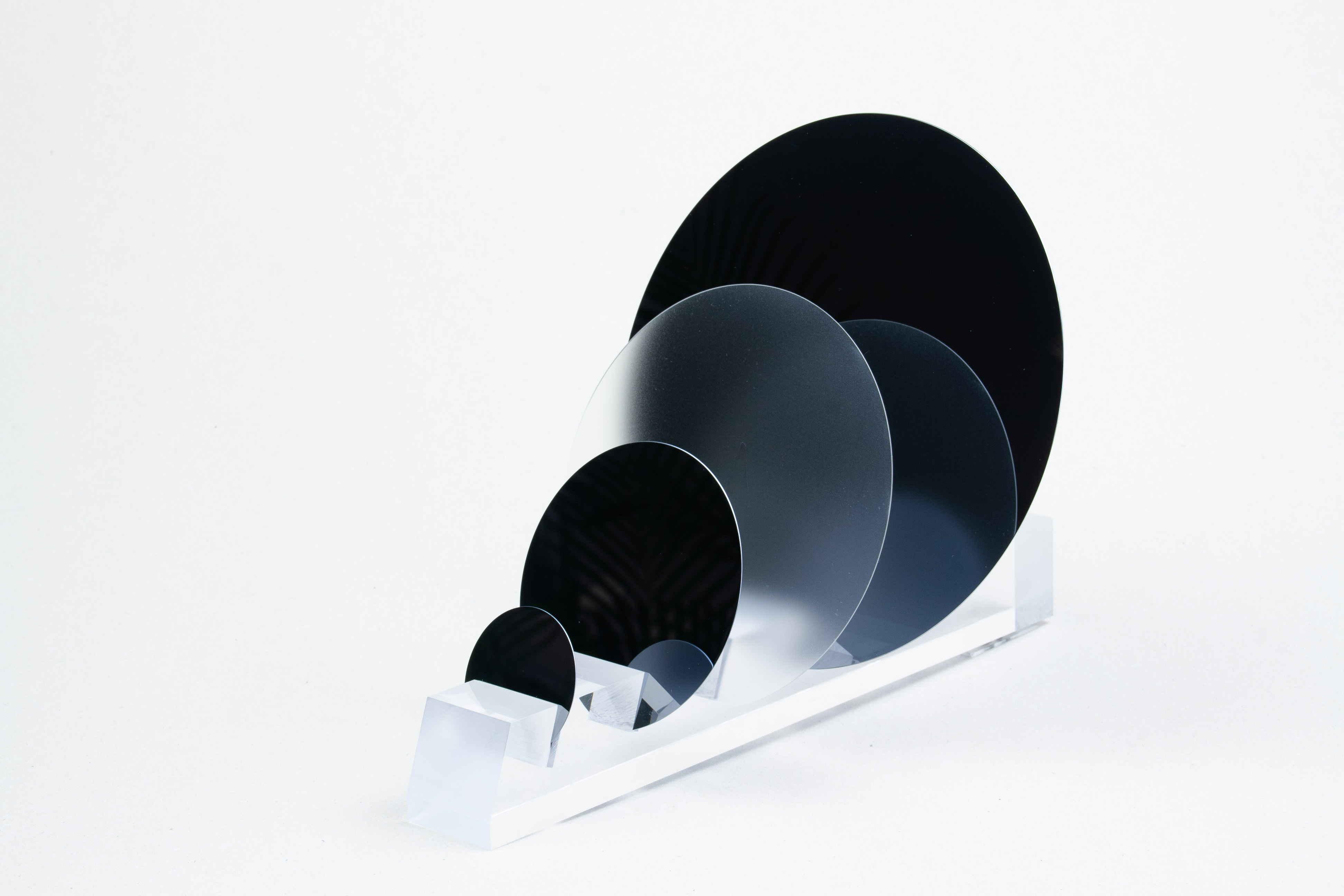

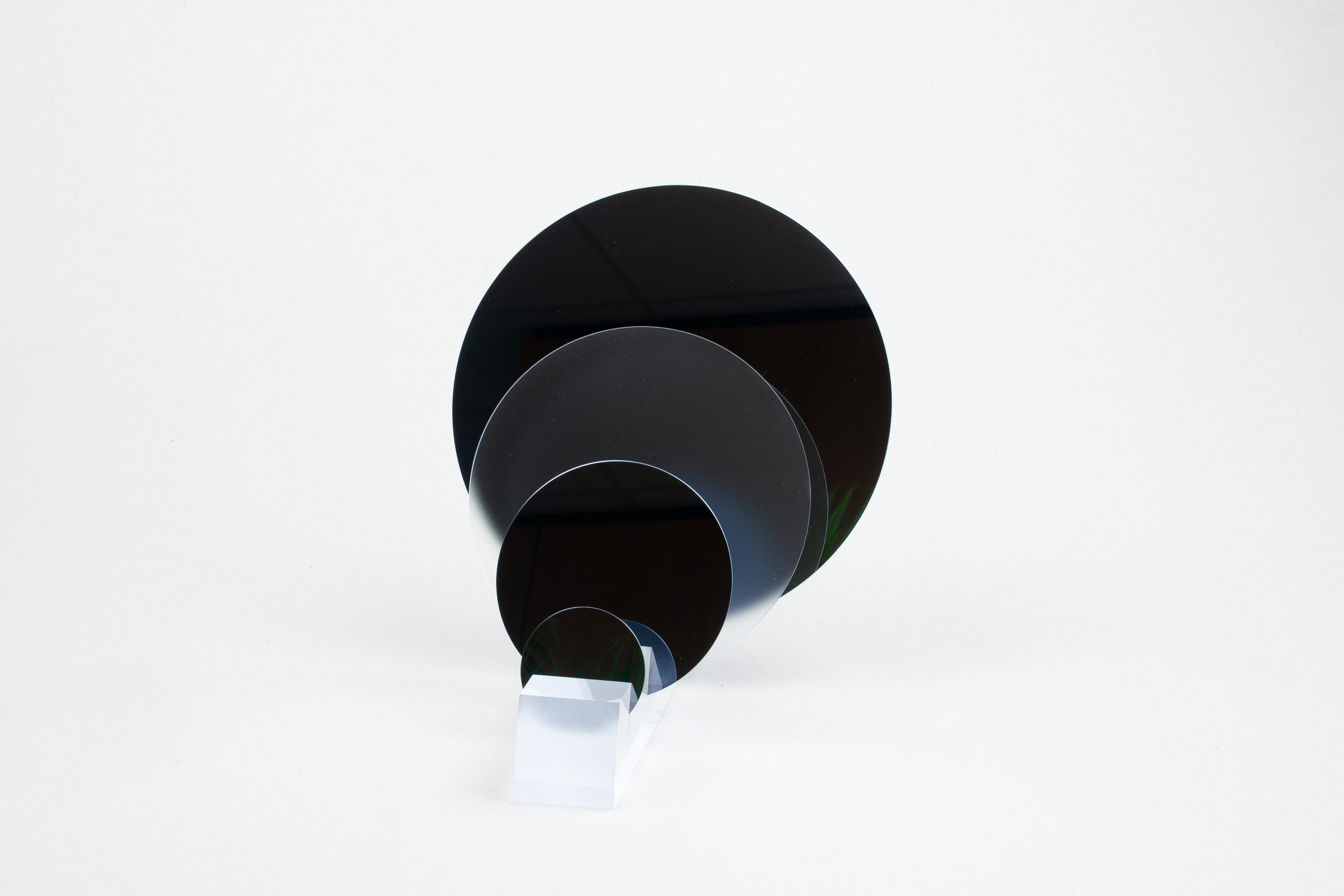

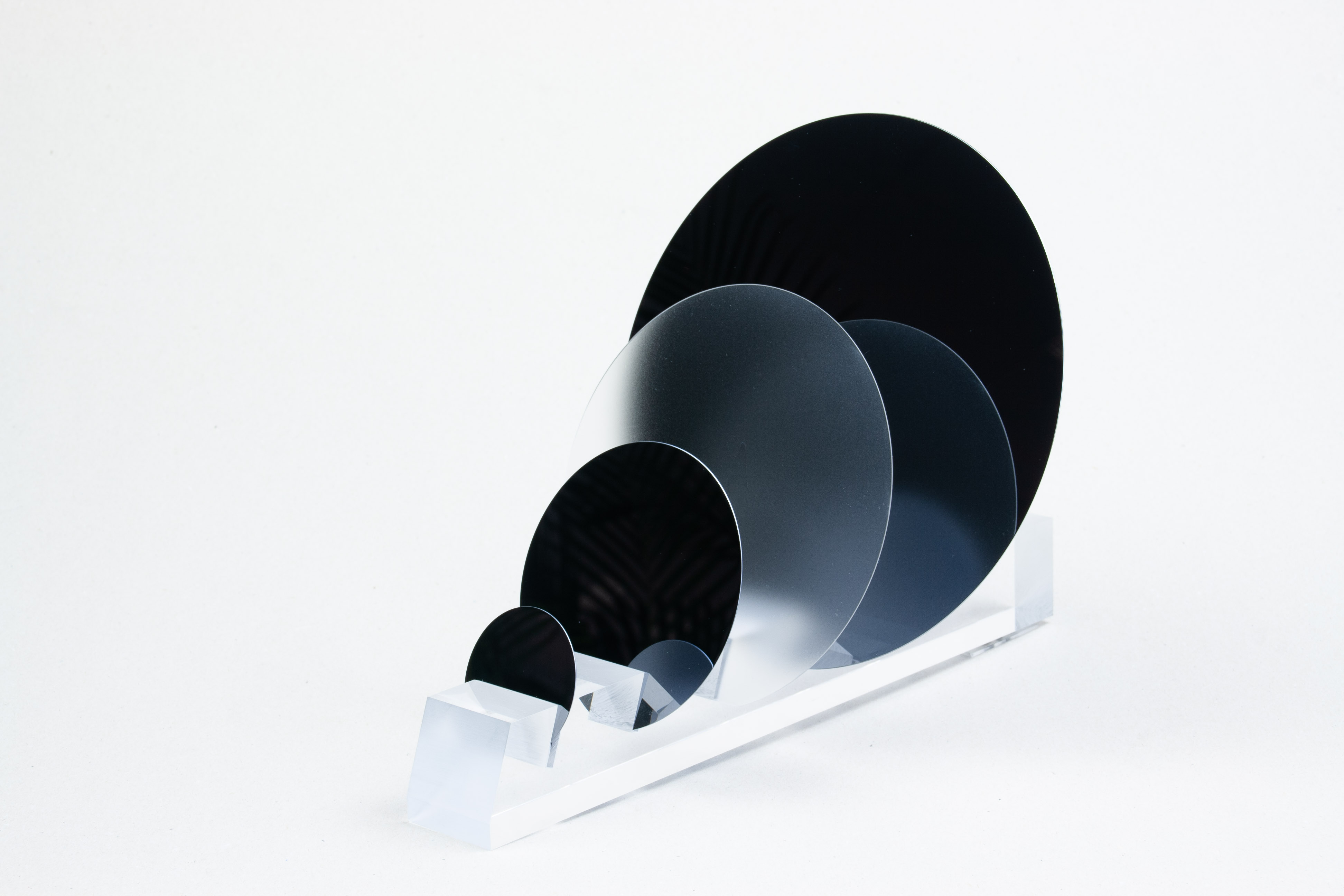

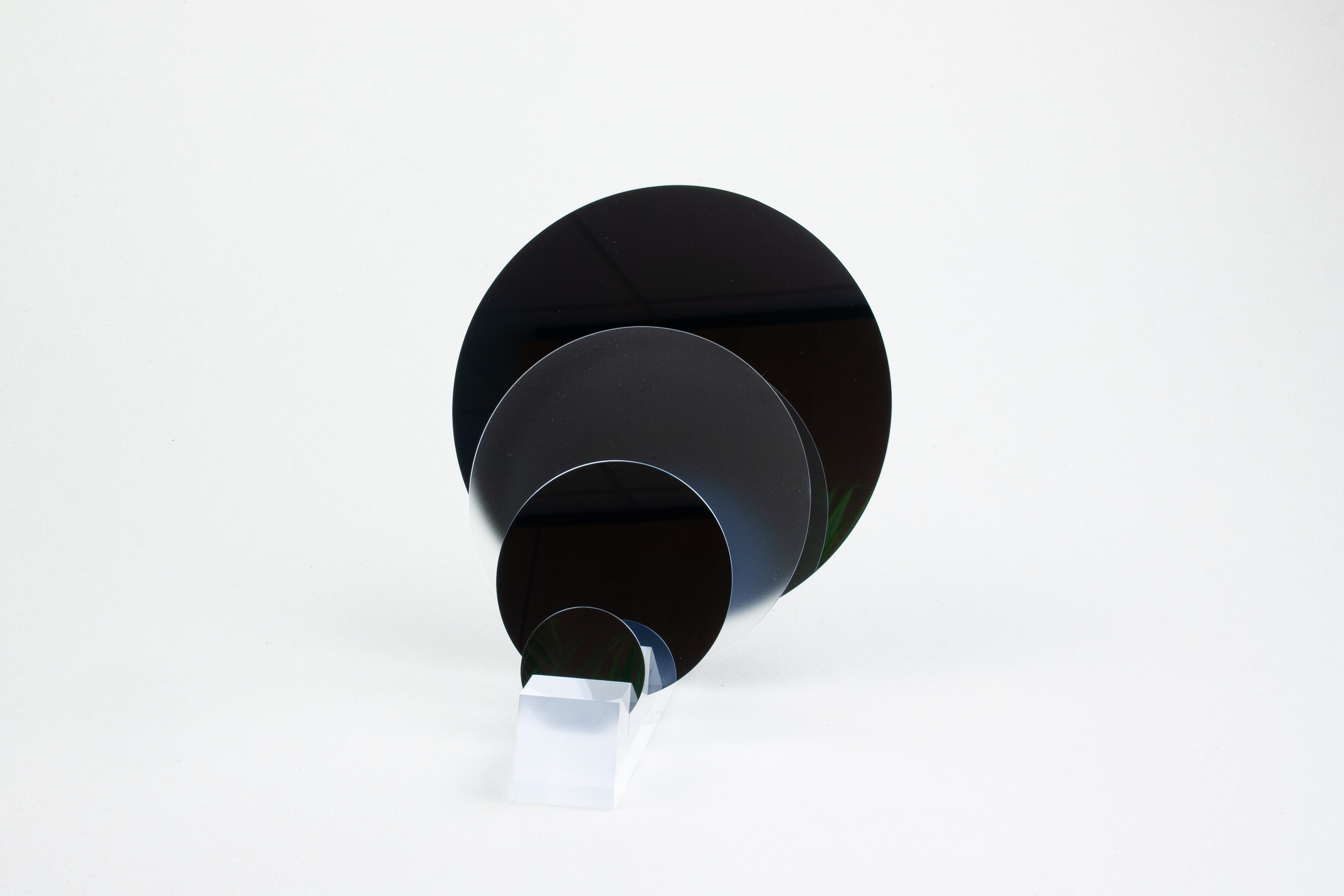

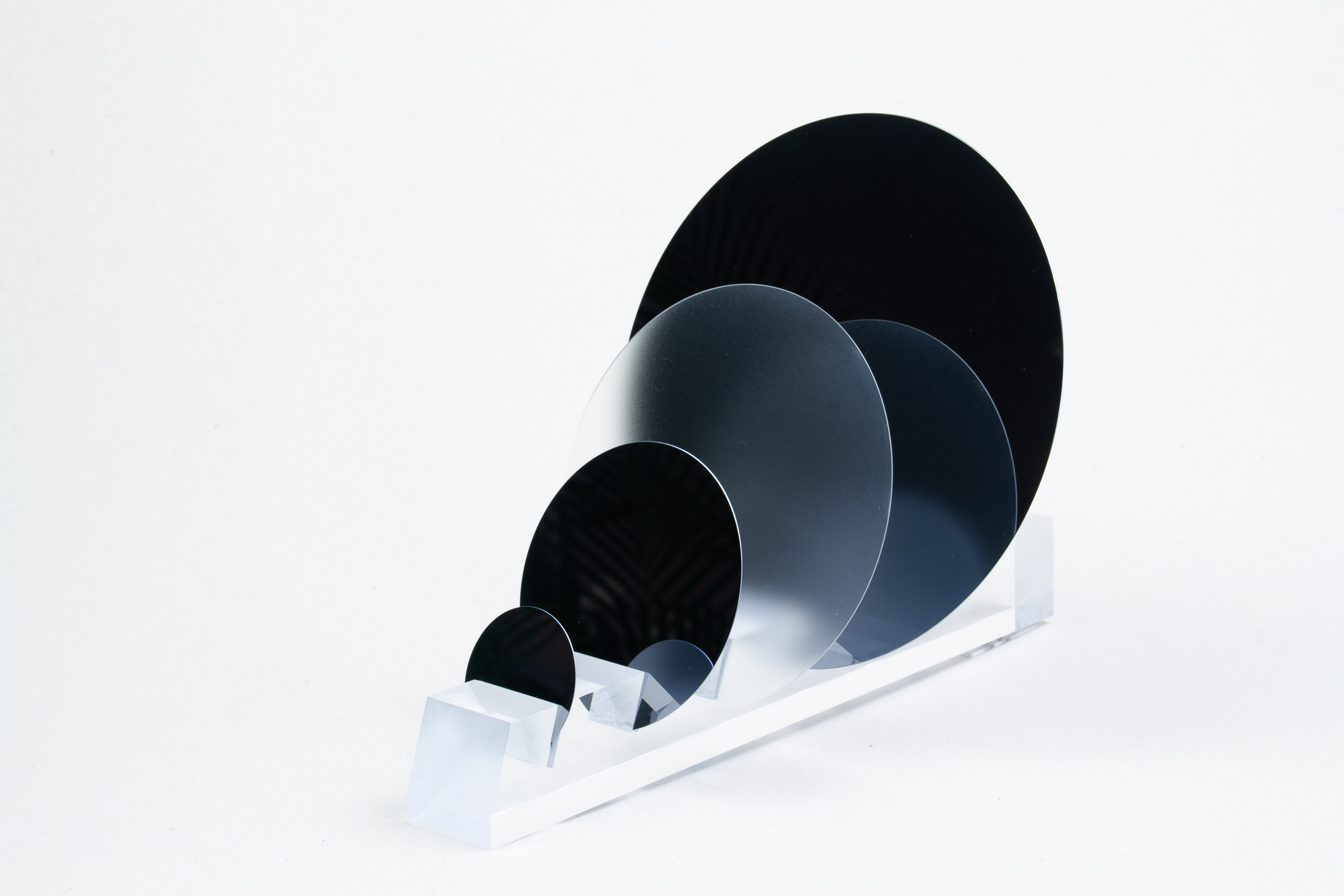

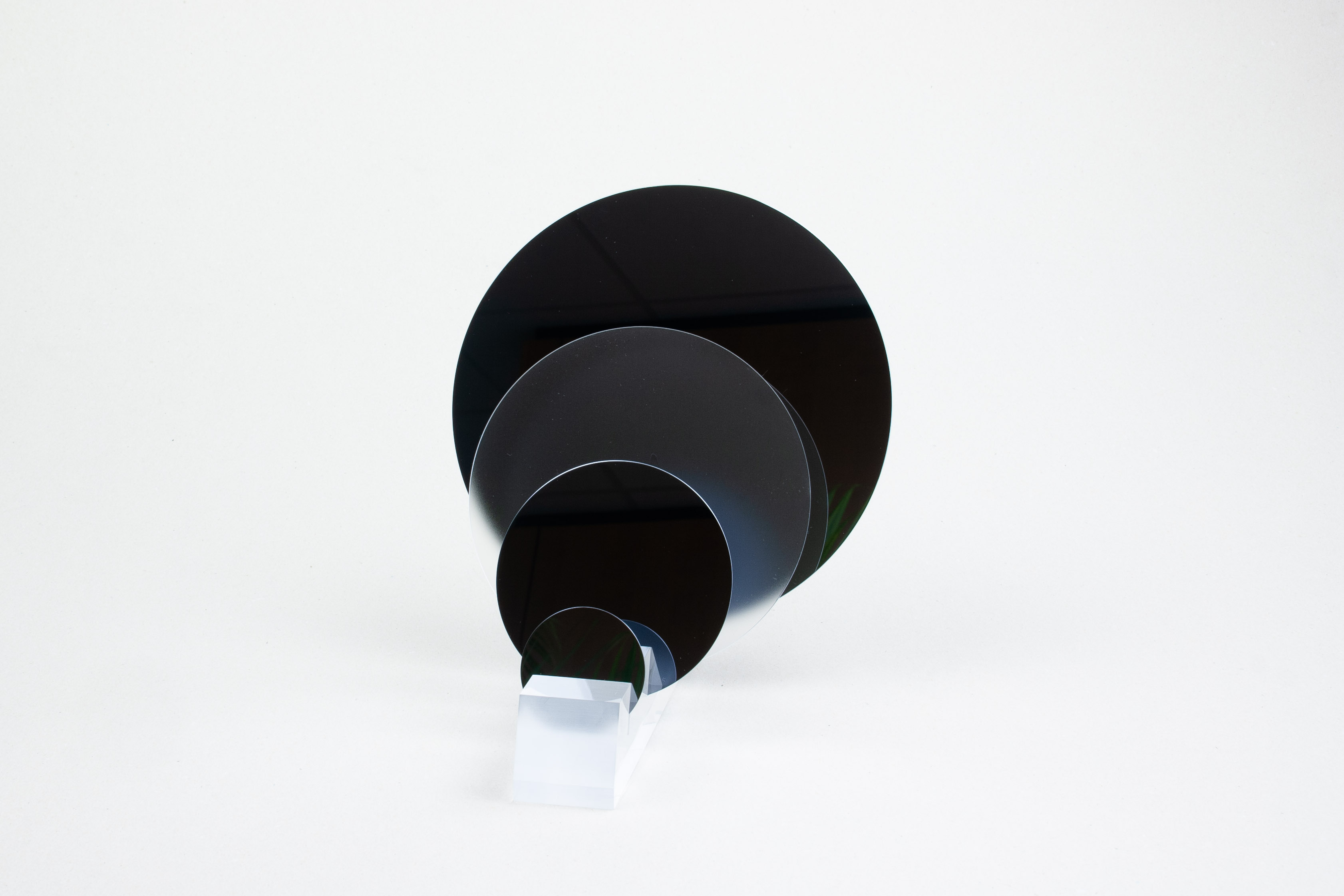

Diameter and dimensions

Available diameters are 2, 3, 4, 5, 6 and 8 inches, other sizes are available on request. Separation into rectangular pieces is also possible, which we are happy to offer on request.

Wafer thickness and surface

Standard thicknesses are 500, 700 and 1100 μm, other thicknesses are available on request The surfaces can be polished on one or both sides. The roughness of the polished side(s) is usually < 1.5 nm.

Further Information:

> Application areas and compatibilities

> Image Reversal Resist Processing

Filter products